If you have assigned flow values to outlet equipment, you can use the instant sizing tool to calculate sizes for ductwork as you draw duct runs. You can also use the instant sizing tool when modifying existing duct runs.

You can calculate duct sizes using either the equal friction method or the constant velocity method. To specify which duct sizing method to use, see Specifying Sizing Parameters for a Duct System. The instant sizing tool calculates capacity by adding the flow values for all outlets detected in the duct run. If no flow values have been assigned to outlet devices, the capacity displayed is zero.

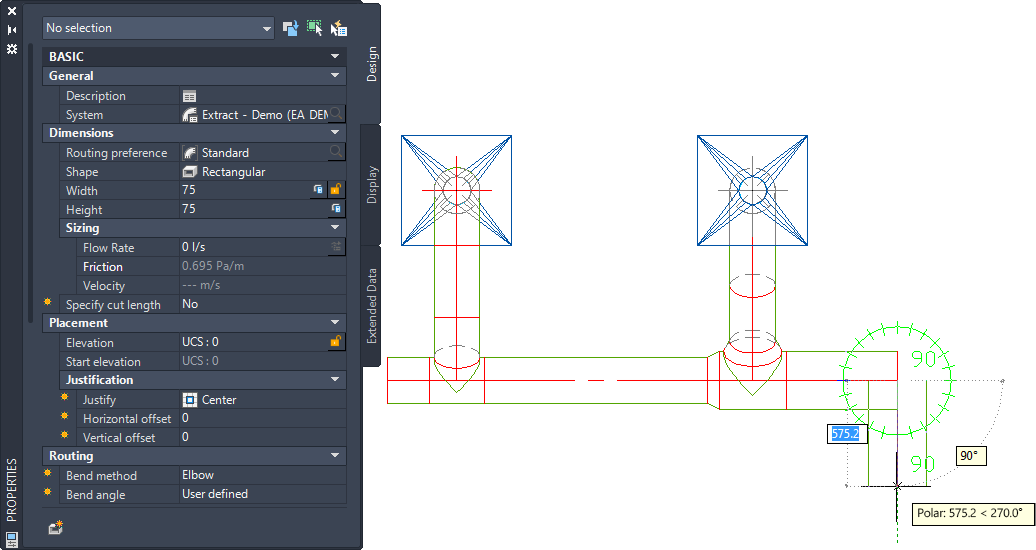

If you are drawing a duct segment connected to an outlet device with a specified flow capacity, the flow value is detected. If you are drawing a branch that is not yet connected to outlet devices, you can select outlet devices to be considered when calculating size. You can also manually enter a flow capacity to be used for size calculations.

The instant sizing tool detects flow capacity of outlet devices connected to the run.

When you execute the calculate size command, the instant sizing tool performs 2 calculations. First, it calculates the exact duct size based on the flow capacity value and a fixed parameter (either friction or velocity, depending on which calculation method is specified). The exact duct size is compared to available duct sizes in the catalog, and the next larger size from the catalog is selected. The velocity and friction values are then recalculated using the duct size selected from the catalog.