The length of a pipe segment is accurately modeled using separate joints. Cut length on the Properties palette is the actual length of the pipe and includes the depths needed to engage the flanges.

Cut length on Properties palette

Cut length refers to the distance between connectors inside a pipe segment. The following diagram differentiates pipe length from cut length, based on CEL (connector engagement length).

The reported cut length value varies depending on the connection type of the attached fitting. For example, with hub flange couplings, the software considers the overall length of the connected object including the coupling length. The following example shows how the software reports the cut length based on this scenario. The overall calculated length includes the pipe length plus the coupling length, as shown next.

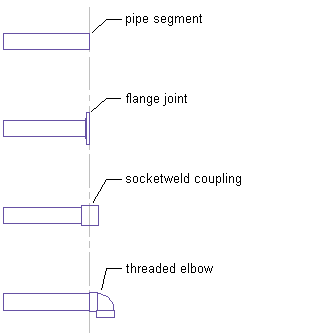

Pipe length varies, depending on what is connected to the pipe. The following illustrations show various pipe examples.

The first illustration shows a pipe segment. The second illustration shows a flange joint added to the pipe segment. The overall length of the pipe and joint is the same as the original pipe. However, the pipe end is moved so that it is in the same location as the flange connector. The pipe length is reduced by the width of the flange, and the CEL (connector engagement length) for the flange is added to the length to calculate the cut length.

The third and fourth illustrations show other fittings connected to the pipe end. If a coupling is added, the midpoint of the coupling is located at the original pipe end location. The pipe end is moved to the adjacent coupling face. An elbow is added at the end of the pipe, and the pipe end stays in the same location. The pipe length stays the same, but the cut length increases because the elbow CEL is added to the length. For each of the connections shown above, the resulting pipe cut lengths vary from the original pipe length.

Joints and fittings have the following effect on pipe segments and cut length:

- When modifying pipe segments using lengthen grips and dynamic dimensions, the dynamic length dimensions do not include CEL values.

- When working with a specific pipe length in a system, such as a stock length, adding or changing a fitting might affect the cut length of a pipe segment.