You can use the Threading tab of the Turning Feature Properties dialog to edit the machining settings for a Thread feature.

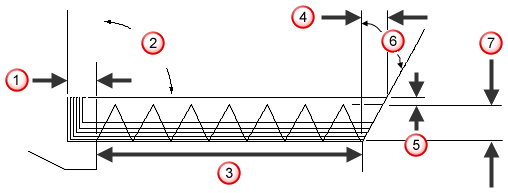

Some of the Threading attributes are shown on this diagram:

|

|

|

|

|

|

End clearance — Enter the distance that the tool feeds past the end of the thread (into the relief groove) before retracting from the part's surface. If Do chamfer on exit is selected in the Machining Attributes dialog or the Strategy tab, this value is the chamfer length.

Infeed angle — Enter an unsigned, incremental value from the positive Z axis.

Start clearance — This value is the position to which the tool traverses before engaging into the workpiece.

Start threads — If set to

1, a single thread is created. If set to

2 or

3, multiple start threads are created. The number of threads per inch (or per mm) for each thread is divided by the number of threads. For example, if you create a thread with 10 threads per inch with 2 start threads, then each thread is 5 threads per inch 180 apart.

apart.

Tool change location is the point where the tip of the tool moves before a tool change.

End clearance

End clearance

Withdraw angle

Withdraw angle

Depth

Depth

Start clearance

Start clearance

Clearance

Clearance

Infeed angle

Infeed angle

Height

Height