You can set Toolpath corner % to any positive percentage. Setting it to a large percentage like 200% or 300% provides a high degree of toolpath smoothing. In this case, where the radius of the cutter is significantly less than the radius of the corner, the percentage of the tool that contacts the part is minimized. This allows the tool to cool and also avoids sharp increases in tool load as it enters the corners.

For high speed machining applications:

- Create at least two roughing passes using Mult. rough diameters parameter. You can set the tool diameters to be the same if you want to use the same diameter for each pass.

- Set the

Toolpath corner % to a high value (for example

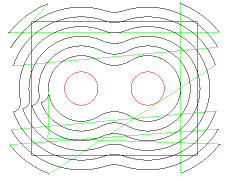

200%) for the initial roughing pass. This pass covers the majority of the part with smooth toolpaths. This image shows an example of smoothing toolpaths using a high corner %.

- Set

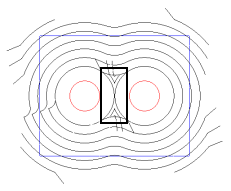

Toolpath corner % to lower values for subsequent roughing passes. These toolpaths cover only the remaining regions of the part. This image shows the second roughing toolpaths.

- It is best to set Tool corner % to less than 25% for the last roughing pass to ensure that the entire part is roughed. These toolpaths initially have more inconsistent tool loads, but you can adjust the stepovers, depth of cut, or feed rate separately for these passes to create acceptable tool loads. You can use the tool loads dialog during 3D simulation to verify the tool loads of your paths before cutting.