You can use the Leads tab of the Surface Milling Properties dialog to control how the tool moves on and off the 3D surface milling feature (lead in/out) and how the tool moves between toolpaths (stepovers).

Stepover type controls the moves between toolpaths.

Ramping

If Ramp to Depth is deselected, the tool plunges to depth. If Ramp to Depth is selected and Helical is not selected, the tool zigzags into the material. The angle of the zigzag passes is controlled by Ramp angle. If Helical is selected, the tool spirals into the material.

Lead Moves

Use lead in/out controls when lead in/out moves are applied.

The Lead in/out plane controls how the arcs and ramps are measured.

Lead moves are performed either as arcs or linear moves by selecting one of the following categories:

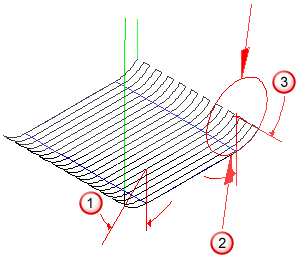

Use arc ramp-in/out

If you select Use arc ramp in/out, the following parameters are used to control the ramping on and off the part feature:

|

|

|

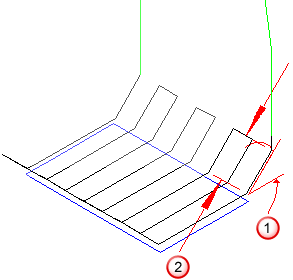

Use linear lead-in/out

If you select Use linear lead-in/out, the following parameters control the move off the feature:

- Lead-in angle - Angle measured away from the toolpath for the lead-in move. Note this angle can be negative.

- Lead-out angle - Angle measured away from the toolpath for the lead-out move. This angle can be negative.

- Lead-in length - Length of the linear lead-in length.

- Lead-out length - Length of the linear lead-out length.

|

|

|

-

Ramp-in angle - The angle of the ramp in move.

-

Ramp-in angle - The angle of the ramp in move.

-

Ramp diameter - The diameter of the ramp move.

-

Ramp diameter - The diameter of the ramp move.

-

Ramp-out angle - The angle of the ramp out move.

-

Ramp-out angle - The angle of the ramp out move.