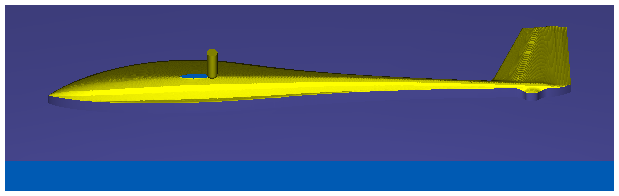

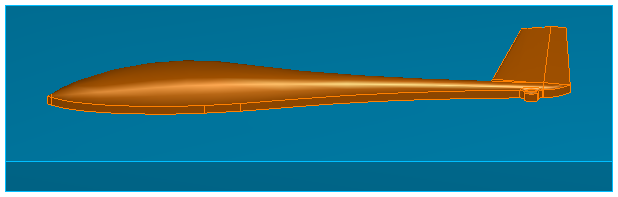

For example, you can use Bottom up to cut this glider mold part:

After a Z-level rough and a 2.5D finish, a Z-level finish strategy is used, with Scallop height to control the shape of the toolpath.

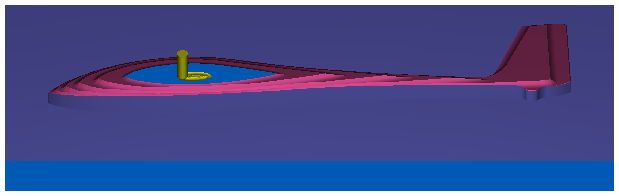

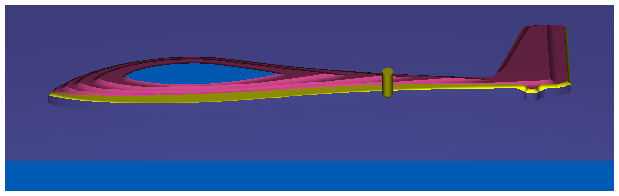

This is a 3D simulation with Bottom up deselected:

The Ball End Mill tool (shown in yellow) starts at the top in the middle cutting outwards and so is cutting with the center of the tool:

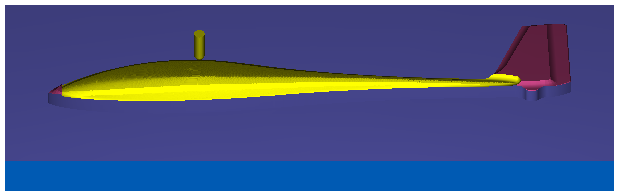

This is the result with Bottom up selected:

The tool starts at the bottom outside of the slope and mills upwards and inwards towards the center so that the side of the tool is used, which has a better cutting surface.