To open this dialog, click the Remachining button on the Strategy tab.

None — Select this option to have no remachining.

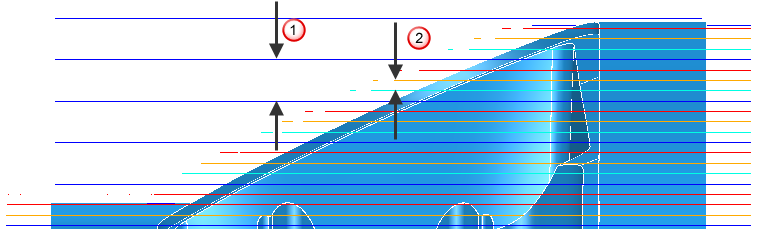

Step cutting — This option machines the terraces that would otherwise remain during a Z-level rough toolpath with the same tool in the same toolpath. The terraces are machined from bottom to top. FeatureCAM increases the feed rate of the intermediate slices as the depth of cut gets progressively smaller, which enables a constant volume removal rate.

Step up — Enter the distance between intermediate cutting levels.

Stepdown of the main slice.

Stepdown of the main slice.

Stepup of the intermediate slice.

Stepup of the intermediate slice.

The main slice clears the majority of the material. The intermediate slices remove the terraces remaining after the main slice.

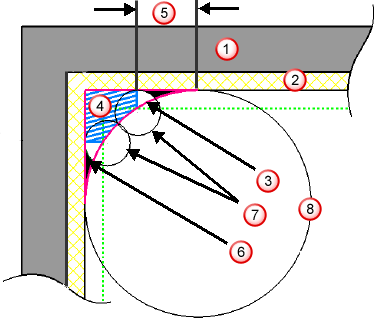

Detect material thicker than — Enter a threshold value. FeatureCAM ignores rest material that is thinner than the specified threshold.

Expand area by — Enter the distance by which to expand the rest areas, measured along the surface. Use with the Detect material thicker than value to reduce the areas to be machined to the details (for examples, corners), and then to offset these areas slightly to ensure that all the detail (for example, on the corners) is machined.

Model

Model

Thickness

Thickness

True rest material (outlined in pink)

True rest material (outlined in pink)

Actual rest material detected (blue hatched area)

Actual rest material detected (blue hatched area)

Amount you need to expand the area by to include all the rest material

Amount you need to expand the area by to include all the rest material

Undetected material (black area)

Undetected material (black area)

Tool

Tool

Reference tool

Reference tool

Increase feed for intermediate steps — Select to increase the Feed rate of the intermediate slices. Because the stepdown of the intermediate slices is less than that of the main slice, you can increase the feed rate of the intermediate slices while maintaining the tool load. Each intermediate slice can have an increasing feed rate as the depth of cut gets progressively smaller.

Maximum feed increase % — Enter the maximum allowable cutting feed rate for the intermediate slices as a percentage of the normal feed rate. This value must be larger than 100%. A value of 300 means the cutting feed rate of the intermediate slices can be up to three times faster than for the main slices.