Plunge roughing provides an alternative form of roughing. With this technique, roughing is performed with a series of overlapping holes. The advantage of using this technique is that parts can be roughed quickly because the force of the operation is directly up the spindle.

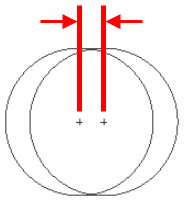

This figure shows a sphere that is being plunge roughed with a flat end tool.

The pattern of drilling operations is parallel to the X or Y axes just like parallel milling. Neighboring rows of the pattern can be offset horizontally to better cover the part.

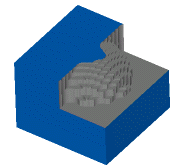

Plunge roughing is performed in either a straight rectangular pattern, as shown below:

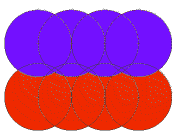

or a honeycomb pattern in which each row is offset horizontally by half the rough pass stepover amount:

The honeycomb pattern is usually preferable. The Honeycomb pattern attribute controls the pattern type.

The Rough pass stepover % attribute controls how far the holes in the same row are spaced. It is specified as a percentage of the tool's diameter.