Introduction

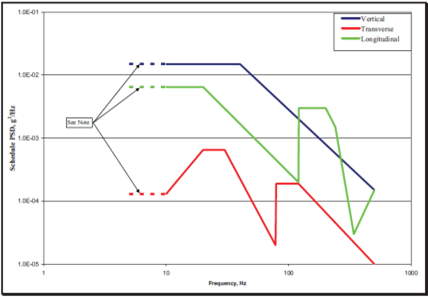

In the previous exercise, we saw that there were normal modes (natural frequencies) that corresponded to higher energy road load inputs. Ideally, the muffler should not excite at those frequencies. If we can modify the design to push the questionable modes out of the peak energy portions of the curve, we will minimize the chance that vibration-related fatigue will occur. The process of moving modes to avoid high energy or excitation frequencies is called modal avoidance.

1. Open the Model and Start the Autodesk Inventor Nastran Environment

Start Autodesk Inventor, and open Muffler&Brackets.iam from the Section 23 - Muffler - Modal Avoidance folder of your training exercises folder.

From the ribbon, click the Environments tab, and click Autodesk Inventor Nastran.

2. Thicken the End Caps and Bulkheads

The 380 Hz and 410 Hz modes are very near the drop off region in the road load longitudinal curve. Pushing these modes up 20 to 25% could reduce their sensitivity to this frequency. We can thicken the bulkheads and end caps to shift these modes.

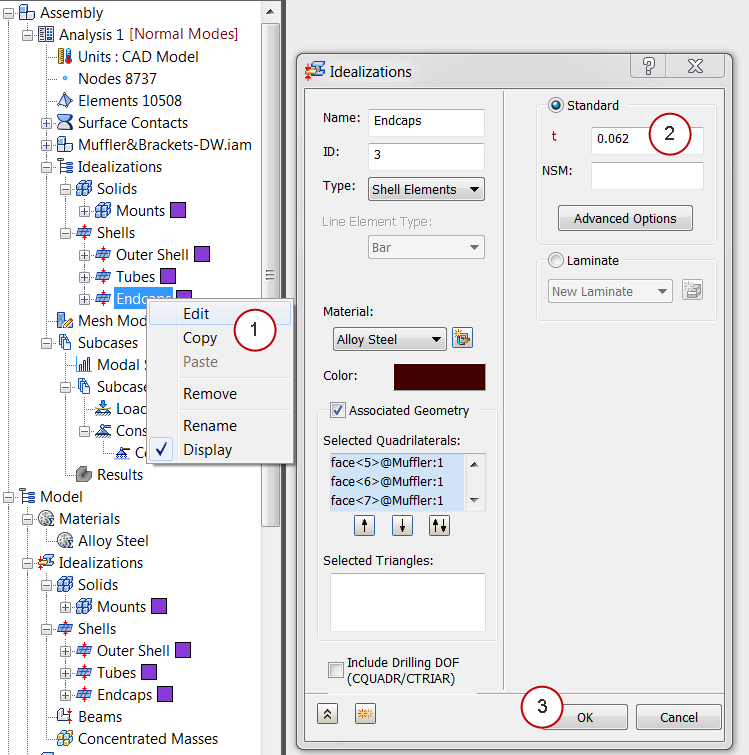

- From the Analysis tree, right-click on Endcaps from the Idealizations list, and click Edit.

- Change the thickness, t, to 0.062.

- Click OK.

3. Thicken the Mounting Brackets

Similarly, the 102 Hz mode is close to the drop off in the road load transverse curve. This would require a 200-330% increase to justify the change. However, increased material thickness on a small part will have a minor cost impact.

- Click Finish Autodesk Nastran to return to the model edit environment in Inventor.

- Right-click on Muffler Mount:2, and select Edit.

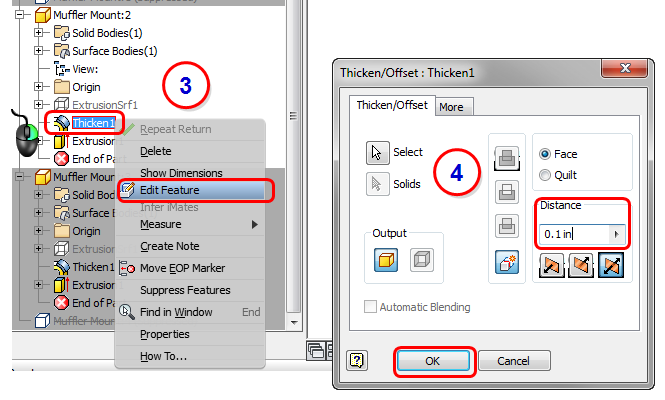

- Right-click on Thicken1, and select Edit Feature.

- Enter a Distance of 0.1, and click OK.

- Double-click on the top branch: Muffler&Brackets.iam (Two Brackets).

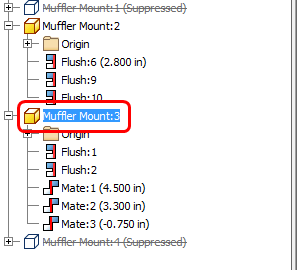

- Repeat steps 2-5 to change the thickness of Muffler Mount:3 to 0.1.

4. Update the Mesh and Run the Analysis

Return to Inventor Nastran by clicking Environments, and then Autodesk Inventor Nastran.

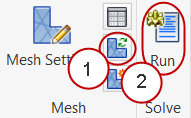

- Because the model has changed, the mesh is out of date. From the ribbon, click Generate Mesh.

- When the mesh is complete, click Run.

5. Review the Results

- Click Options, and expand the Subcases menu to see the frequency for each mode.

|

First Design |

Second Design |

Mode Shape |

|

|---|---|---|---|

|

Mode 1 |

95 |

101 |

Same |

|

Mode 2 |

379 |

564 |

Transverse |

|

Mode 3 |

405 |

625 |

Longitudinal Oil Canning |

We can see that the longitudinal modes were pushed exactly where they needed to go to minimize the possibility of vibration-related failure.

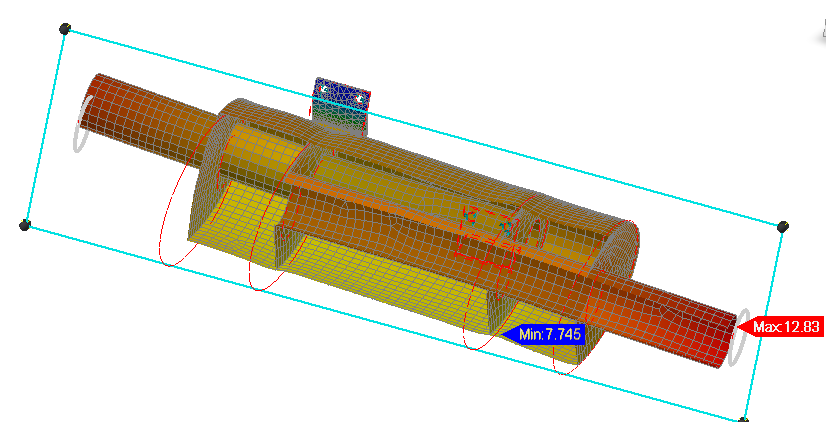

Mode 1:

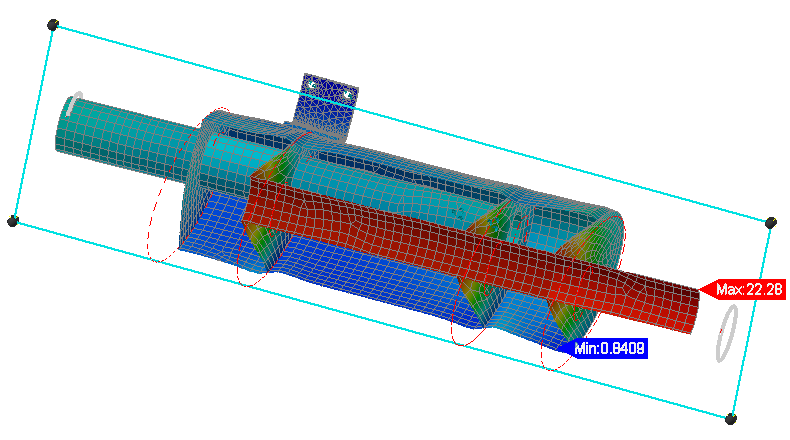

Mode 2:

Mode 3:

Summary

In this exercise we modified the geometry to drive the questionable modes out of the peak energy portions of the curve. This was done by increasing the thickness of the end caps and the brackets.

|

Previous Topic: Modal Analysis Exercise |

Next Topic: Frequency Response Analysis |