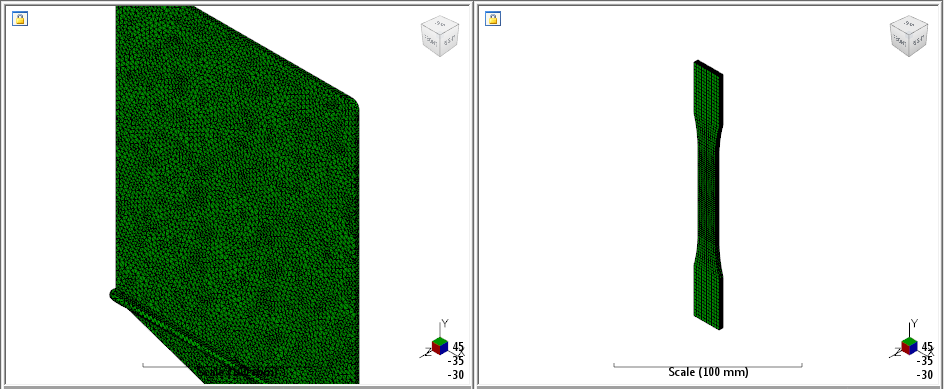

This tutorial guides you through the analysis of an American Society for Testing and Materials (ASTM) coupon specimen which has been machined from an injection-molded plaque. An injection molding simulation is performed with Moldflow and the coupon is created with Inventor Nastran. Advanced Material Exchange is used to map fiber orientations to the structural model and characterize the nonlinear material behavior. Finally, a structural analysis is performed and results are evaluated in Inventor Nastran.

This tutorial is based on ASTM D638-10 for tensile testing of plastic materials. The major goal of this tutorial is to demonstrate that the material models used by Advanced Material Exchange can accurately reproduce the experimental stress-strain response of the material. We will also examine some of the key solution variables produced by Advanced Material Exchange that can help evaluate the structural life of your part.

The models used in this tutorial are available for download here.