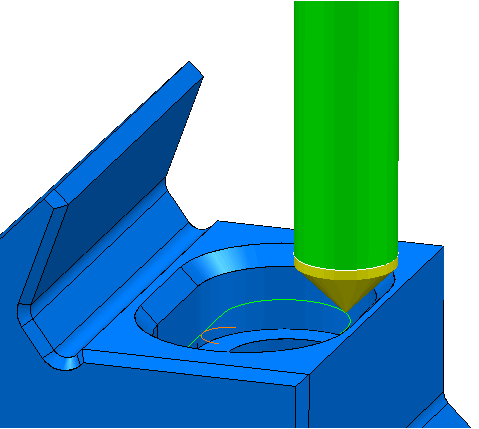

Use the Chamfer Milling strategy to bevel sharp corners using specific chamfer tools. Chamfer milling is used to break sharp outside-edges of a model after it has been completely machined. Chamfer milling:

- minimises hand deburring operations

- improves part assembly, by adding a taper to one or both mating edges

- is used for aesthetic and safety reasons.

Chamfer milling produces a single finishing pass as chamfer tools are larger than the chamfer feature.

There are several pages associated with the Chamfer Milling strategy:

- Chamfer milling — The main page used to define a chamfer.

- Cut distances — Settings to enable multiple passes.

- Finishing — Settings to specify a final stepover or stepdown depth of cut value.

- Order — Settings to control the order of machining.

- Automatic verification — Settings to automatically verify toolpaths on creation.

The remaining pages are common toolpath strategy pages.