Use the Order page to control the order of machining. The available options are dependent on the selected strategy:

Order by — Select whether machining takes place by Level, Pocket or Region.

-

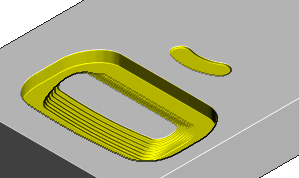

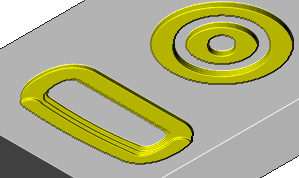

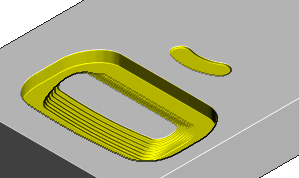

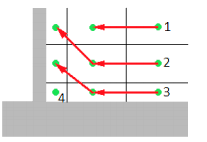

Pocket — When selected, one pocket is completely machined before going on to the next. Pockets are machined in preference to levels.

-

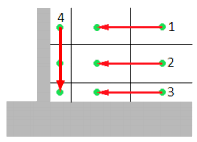

Level —When selected, one level is completely machined before going down to the next. So, levels are machined in preference to pockets.

-

Region — When selected, one region (such as a pocket or boss) is completely machined before going on to the next. So, pockets are machined in preference to levels.

Priority — Select the regions that are machined first. This option is only available for Feature Finishing and Steep and Shallow Finishing strategies:

- Top first — Select this option to machine from the top regions downwards. If you have a boss, the flat at the top is machined before its walls. If you have a pocket its walls are machined before the flat at the bottom.

- Wall first — Select this option to machine the walls of a feature before its flats. If you have a boss, its walls are machined before the flat at the top. If you have a pocket its walls are machined before the flat at the bottom.

- Steep first — Select this option to machine the steep regions before the flat regions. If you have a boss, the constant Z (steep) regions are machined before the shallow regions.

Sorting

— Select an option to specify the toolpath order. Unless you select the

Explorer order

— Select an option to specify the toolpath order. Unless you select the

Explorer order

option the start point is the feature nearest to the tool start point.

option the start point is the feature nearest to the tool start point.

Order — Select the order of machining within a region or level. This option is available only if you select an Order by of Region.

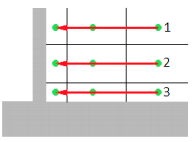

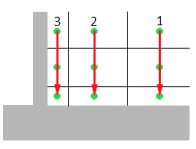

- Width first — Select to remove material to a given width before proceeding to the next Z height.

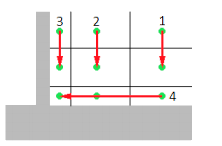

- Depth first — Select to remove material to a given depth before proceeding to the next level.

Group wall passes — Select to machine all wall passes, of different levels, at the end.

Group floor passes — Select to machine all the floor passes, together, at the end. This option is only available if you create a 2D Curve Profile toolpath. This option is available only if you select an Order by of Region.

For more information on the ordering of toolpaths see Ordering options.

Maintain cut direction — Select this option to maintain the Cut direction specified on the main page. Deselect this option to let PowerMill create a toolpath with fewer tool lifts. PowerMill adheres to the specified cut direction as far as possible, but gives proirit to fewer tool lifts.

Feature finishing

The following options are available only for Feature Finishing strategies:

Sequence — Select an option from the list to specify the whether walls or flats are machined first.

-

Width first — Remove material to the width specified on the

Wall cut distances page before stepping down.

-

Width first with final wall passes — Remove material to the width specified on the

Wall cut distances page except the final wall pass before stepping down. Then perform a final pass that removes the remaining material at all Z heights.

-

Thin walls — For each Z height, remove material to the width specified on the

Wall cut distances page except the final wall pass, then machine the remaining material from the previous Z height.

-

Depth first — Remove material to the depth specified on the

Flat cut distances page before stepping over.

-

Depth first with final floor passes — Remove material to the depth specified on the Flat cut distances page except the final floor pass before stepping over. Then perform a final pass that removes the remaining material for the final Z height.

Port area clearance

The Order page for port area clearance strategies contains unique options to specify which ends of the ports are used and how far to machine down each end of the port:

- Maximum from end — Machines as far as possible from the end of the port before trying to machine from the start of the port.

- Maximum from start — Machines as far as possible from the start of the port before trying to machine from the end of the port.

- Evenly from ends — Machines equally down both ends of the port.

- From end only — Machines only as far as possible down the end of the port.

- From start only — Machines only as far as possible down the start of the port.

Spiral — Select to spiral inside slices.

Partial — When selected, if there are full slices which cannot be machined from either end, then Partial machines the maximum possible area (while avoiding collisions). This calculation is slower and some rest material will remain.