When you have an Embedded pattern you can use it to define the tool contact point of a toolpath. This example looks at an engraving toolpath. The Embedded Pattern Finishing dialog is similar to the Profile Finishing dialog.

- Click Home tab > Create Toolpaths panel > Toolpaths to display the Strategy Selector dialog.

- From the Finishing category, select Embedded Pattern Finishing.

- On the Tool page, select

from the Tool list. This displays the Tapered Spherical Tool page.

from the Tool list. This displays the Tapered Spherical Tool page. - On the Tapered Spherical Tool page:

- Enter a Diameter of 3.

- Enter a Tip Radius of 0.2.

- Enter a Taper Angle of 30.

- Enter a Length of 15.

- On the Tool axis page:

- Select a Tool Axis of Lead/Lean.

- Enter a Lead of 0.

- Enter a Lean of 0.

- Select a Mode of Contact Normal.

- On the Embedded pattern finishing page:

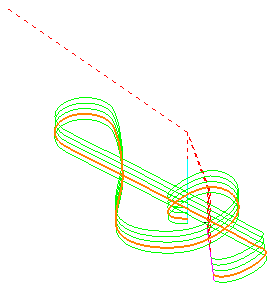

- In the Drive Curve frame, select an Embedded Pattern of TrebleClef_1 (created in Creating an embedded pattern example).

- In the Lower Limit frame, select an Axial Offset of -1.

- In the Gouge Avoidance frame, deselect Gouge Check. Because you are engraving the surface, you want the toolpath to gouge the surface.

- On the Multiple Cuts page:

- Select a Mode of Offset Down.

- Select an Order by of Level.

- Deselect Maximum Number of Cuts.

- Select Upper Limit and enter a value of 3. This option is only available when you select the Mode of Offset Down.

- Enter a Maximum Stepdown of 1.

- Click Calculate to create the embedded toolpath.

Note: You can see that the lowest pass of the toolpath is 1 mm below the embedded pattern. You get a difference between the toolpath and the embedded pattern as the embedded pattern is at the tool contact position and the toolpath is at the tool tip position.