Use the Corner clearance page to remove material left in corners, in successive stages.

Segment type — Selects the type of machining.

-

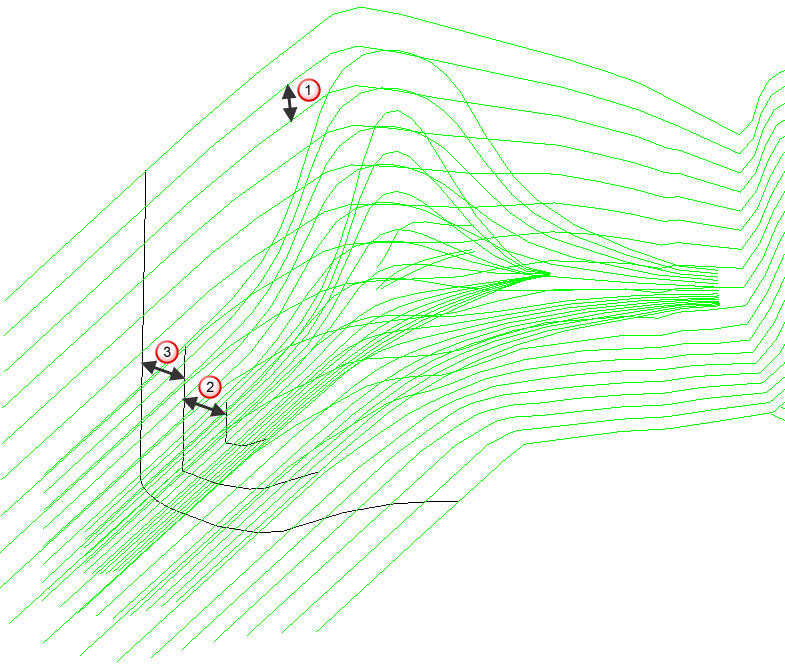

Horizontal stitches — Is the default setting for steep region machining. Steep regions are machined with horizontal stitches by default. You can select Along passes to machine steep regions.

Horizontal stitches:

Steep stepover

Steep stepover  Steep depth of cut

Steep depth of cut Steep final depth of cut

Steep final depth of cutAlong passes:

Steep stepover

Steep stepover  Steep depth of cut

Steep depth of cut Steep final depth of cut

Steep final depth of cut

-

Vertical stitches — Can be used for shallow region machining. Shallow regions are machined with along passes by default. You can select Vertical stitches to machine shallow regions.

Along passes:

Shallow stepover

Shallow stepover Shallow depth of cut

Shallow depth of cut Shallow final depth of cut

Shallow final depth of cutVertical stitches:

- Along passes — Is the default setting for shallow regions. Along passes can be used on both steep and shallow regions.

Stepover — Enter the distance between successive machining passes.

Depth of cut — Enter the thickness of material removed by each cut.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Cut direction — Select the milling technology.

Select a Cut Direction from the following:

-

Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

-

Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling. This minimises the tool lifts and tool travel.

Thickness — Enter the amount of material to be left on the part. Click the

Thickness

button to separate the

Thickness

box in to

Radial thickness

button to separate the

Thickness

box in to

Radial thickness

Axial thickness

Axial thickness

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Component thickness — Click to display the

Component thickness

dialog, which enables you to specify the thicknesses of the different surfaces.

Component thickness — Click to display the

Component thickness

dialog, which enables you to specify the thicknesses of the different surfaces.