Use the Extension Distance Options page to specify the extension of the electrode that attaches the burn region to the base. This page of the Electrode Wizard is colour-coded to show which part of the electrode the values refer to.

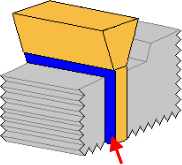

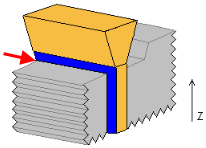

This diagram shows an electrode (yellow) positioned in a solid workpiece (grey). The extension distance (blue) is marked with an arrow:

- Enter a value in Extension Distance to specify the extension.

- Enter values in the Z and XY scale boxes to specify how much you want to scale the extension by in the Z direction, and in both the X and Y directions.

Note: If you enter different scale values in the Z and XY fields, the resulting extension is still tangent-continuous with the underlying faces of the solid. Therefore the actual distances extended may not equal the distance multiplied by the scale factor. Normally, you do not enter two scale values. One of the scale values remains 1 to match the length of the extension distance. If the other value is 1, then the extensions in the Z and XY directions are the same. If it is not 1, the extensions in the Z and XY directions are different.

- Select a method from the Option list to specify how the burn region is extended.

Not all burn region extension options are suitable for all electrodes. Use the Preview button to test the options with your electrode.

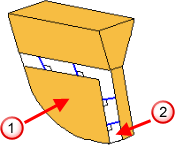

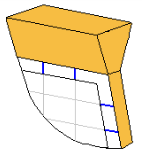

Choose from the following options:- Normal to Edge — The extension is perpendicular to the edge of the burn region:

Burn region

Burn region

Extension

Extension

- Grow to Box — This option uses an expanded bounding-box of the burn region as a target to limit the extension. The surfaces are generally extended further than the extension distance until they intersect with this box. This produces a square, planar side to open-ended ribs.

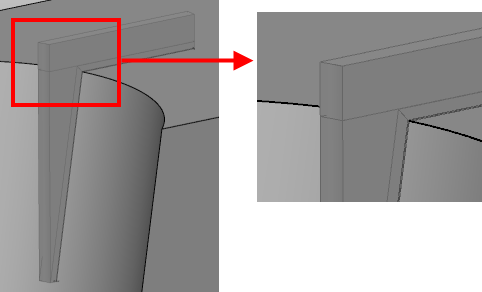

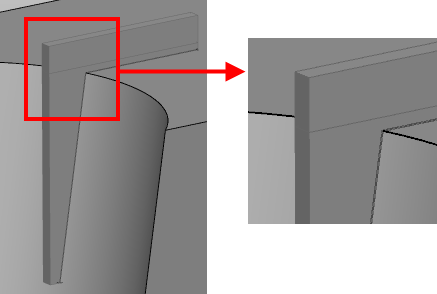

The normal extension methods may not give the desired result because the angle on the edge of the rib produces an angled face on the electrode in the clearance region where the shape is not critical.

The Grow to Box solution gives a neater electrode.

The greater the curvature of the edge of the rib, the greater the benefit of using Grow to Box.

-

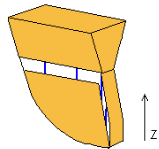

Surface Internals — The extension is along the direction of the laterals/longitudinals on the underlying surface of the burn region.

- Align Vertically — The extension is aligned vertically along the Z axis.

The internal curves of the extension are aligned with the Z axis, but the extension itself is still tangent continuous to the burn region. For this reason, this option is not suitable for extending faces that lie flat in the XY plane.

- Split surface — The extension is along the surface normal of the underlying surface. Select this option and enter a value in Angle. The default angle for the split surface is 90 degrees.

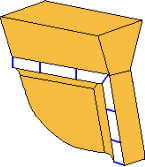

This option is most suitable for convex upstand regions. Without this option, you get a razor edge. In the diagram below, you can see an example of such a region. The arrow shows the direction of the extension.

Split surface option:

Other options:

Burn region

Burn region

This option is also suitable for regions that have fillets at their edges.

- Normal to Edge — The extension is perpendicular to the edge of the burn region:

- Enter a value in Clearance Distance. This is the distance of the electrode base from the selected Position option, measured along the Z axis:

Above burn region

Above burn region

Above extension

Above extension

Above block

Above block

Above minimum Z distance

Above minimum Z distance

You can enter a negative value for the clearance distance. When the base is created, Electrode automatically trims it so that it does not collide with the solid. If the negative value is low enough, you can create an electrode whose base matches the top of the solid. This is known as an offset base electrode.

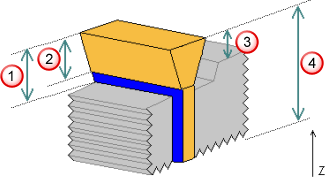

- Choose an option from the Position list. The graphic in the wizard changes to show where the base position is calculated. Choose from:

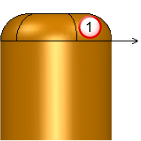

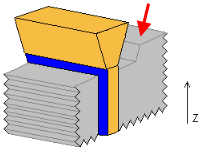

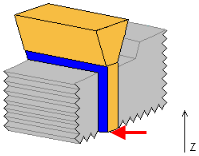

- Above Block — This is the highest point of the solid from the XY plane, marked with the red arrow:

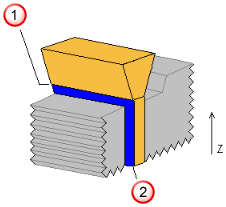

- Above Extension — This is the highest point of the extension of the burn region from the XY plane:

Above Extension

Above Extension

Extension Distance

Extension Distance

- Above Burn Region — This is the highest point of the burn region from the XY plane, marked with the red arrow:

- Above Z min — This is the minimum Z value of the selected burn region, marked with the red arrow:

For this option, you cannot use negative values for the clearance distance. If the clearance distance is less than the height of the burn region, an offset base style electrode is created.

- Above Block — This is the highest point of the solid from the XY plane, marked with the red arrow:

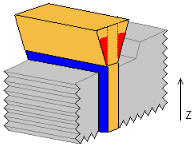

- Enter a value in Draft Angle to specify the angle on the extension of the electrode, excluding the part which extends from the burn region. A draft angle may be required to strengthen the electrode if it is designed for a narrow cavity. It is measured from the Z axis. The draft angles are marked in red on the diagram:

- Click Preview to collision-check the extension and clearance surfaces against the workpiece, and display the electrode in the graphics window. Change the values if necessary and click Preview again.

- To specify different directions for different segments of the electrode extension, click Advanced.

- Click Next. The extension and clearance surfaces are collision-checked against the workpiece again, before the Specify Electrode Blank page is displayed.

Alternatively, click the

button to exit the Electrode Wizard. The electrode is created as a solid and remains selected. You can modify the solid and enter the wizard again. This will register the solid as an electrode.

button to exit the Electrode Wizard. The electrode is created as a solid and remains selected. You can modify the solid and enter the wizard again. This will register the solid as an electrode.