Moving Surface Parts

When thin volumes are set into motion, the mesh requirements in the part itself and in the motion path in the flow can be quite severe. The moving volume must have a mesh that is fine enough to resolve the gradients through its thickness, and the flow path must have a correspondingly fine mesh.

To provide a more convenient method of analyzing the motion of thin objects, the Motion Module supports moving surface parts. This reduces the meshing requirements on both the moving part (because it is a surface part) and the motion path in the surrounding fluid:

On the Materials task dialog, create a surface part by assigning a solid material to the intended surface. The properties of the material and the shell thickness are used to compute the mass of the part, and influence the movement for flow-driven motion. For user-prescribed motion, the physical properties do not influence the motion. On the Motion dialog, change the selection mode to Surface, and select the surface or surfaces that are to move.

Guidelines

- Any of the motion types can be applied to moving surfaces. The motion can be user-prescribed or flow-induced.

- Surface parts cannot be coupled with moving solids using Motion Groups. Surface parts can, however, be grouped with other surface parts in Motion groups.

- Moving surface parts cannot contact moving solids at their starting location.

- Moving surface parts can fully enclose a region.

- Moving surface parts do not have to be planar--they can be arbitrarily shaped.

- Moving surface parts must not come into contact with parts that are extrusion meshed. The interaction between surface parts and extrusion meshed parts is not supported.

- While moving surface parts can initially touch non-moving solid parts, they should not be in complete contact with a solid at their starting point. The reason is that after a small amount of movement, fluid will be trapped between the surface and the solid, and the pressure in the fluid may be very high.

- To add clarity when visualizing the results of a motion analysis with a moving surface part, the moving surface is shown with a virtual thickness. This thickness is purely graphical, and does not influence the motion or the flow around the part.

- The meshing requirements in the path of a moving surface are significantly reduced compared to the path of a moving volume. Unlike moving volumes, the solid elements do not mask the underlying fluid elements, and the fluid mesh does not have to be fine enough to resolve the solid.

The mesh should, however, be fine enough to resolve the pressure gradients on the surface. Likewise, the mesh within the fluid surrounding the moving shell should be fine enough to allow flow to pass around the surface as it moves.

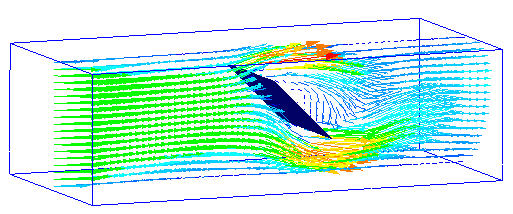

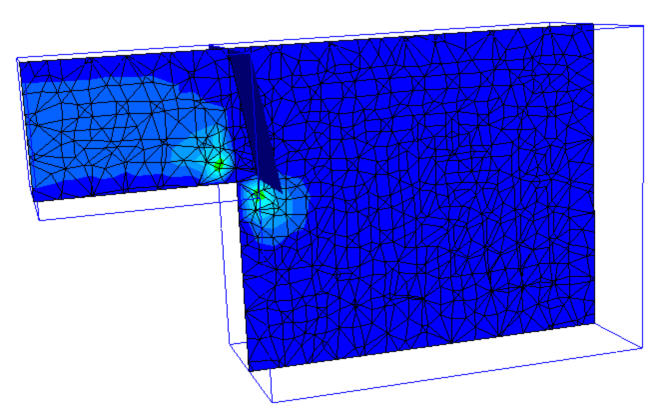

In the following image, the 3D mesh surrounding the moving shell is quite coarse. As the valve opens due to the force of the fluid, very little fluid can pass around it until it has opened about half way.

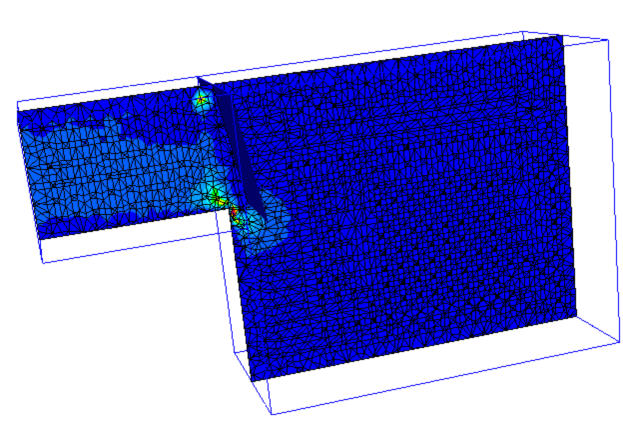

In reality, fluid would leak past such a valve at the onset of motion, and is shown in the model with a finer mesh:

Keep in mind that the amount of “bookkeeping” necessary to track the motion of a moving surface is similar to that of a moving solid. Because of this, moving surface motion analyses are as resource intensive as moving solid analyses, for a given mesh density. The advantage of moving surfaces is that the mesh in the motion path does not have to be as dense as for a moving solid analysis.