The option is used to determine code parameters of a member type. The option becomes available by selecting the New member type option in the Member type dialog box or by pressing the Parameters button in the Definitions dialog box.

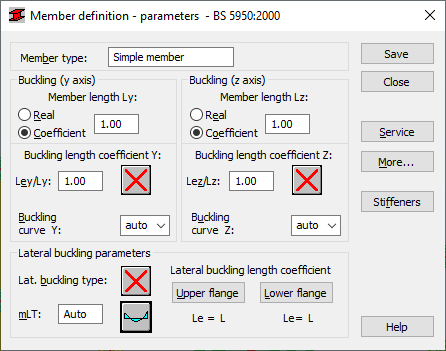

A name of a selected member type is specified in the Member Type field (any name of the defined member type may be entered here). In the Buckling (y axis) and Buckling (z axis) fields, the length of a member for the appropriate plane may be determined. There are two ways of defining this length:

- once the Real option is selected, the value entered is interpreted directly as member length

- once the Coefficient option is selected, the value entered is interpreted as the coefficient by which the real member length should be multiplied to obtain the required value. For example, if the value 0.25 is entered, it means that the relevant member length equals 1/4 of the real length.

For a simultaneous definition of several members whose actual lengths differ and e.g. additional supports are equally spaced, the second method mentioned is very convenient. If the parameters set are to be saved as a category, such a manner of entering the length is necessary. If the value 1.0 is entered, it guarantees that each member defined using the category as Ly will have its actual length accepted.

Member buckling length coefficients in both directions may be defined in the Buckling Length Coefficient field. The actual bar length (or the sum of the component member lengths) is automatically entered in the appropriate fields.

Buckling length coefficient depends on the end-support condition of the member nodes in the buckling plane. Buckling length of a member may also be defined in the Buckling Types dialog box, opened by pressing the icon representing the selected buckling model type. Typical member support schemes are provided here; when one of them is selected, the coefficient value will be accepted or calculated automatically.

The icons in the dialog box are divided into two groups: the first one contains typical (code) methods of member support and the corresponding values of buckling coefficients, whereas the other one contains icons of options used for calculating buckling coefficient for columns of multi-story frames.

Buckling is considered in calculations always when a compressive force acts on a member, even if it is negligible in comparison to other internal forces. The program does not perform - on its own - a separate analysis that would determine if buckling effects may be disregarded or not. If the user wants to exclude buckling effects from the calculations, the last icon must be chosen. If pressed, buckling will be disregarded in the calculation process.

The Buckling curve options enable the program to adopt buckling curves. If the auto option is chosen, then the program will select by itself - a buckling curve appropriate for the section applied according to table 23 of the code; in other cases the program performs calculations assuming the buckling curve defined by the user.

In the Lateral Buckling Parameters field the user may select options used during verification of member lateral buckling: lateral buckling type, mLT coefficient value and lateral buckling length coefficient for the upper and lower flange. Pressing the appropriate icon opens the dialog box for definition of appropriate parameters.

The Lateral Buckling Type option is used to define proper code lateral buckling parameters depending on the static pattern of the member. As required by the code, one of the patterns included in the code should be accepted. The patterns in the form of icons reflect exactly the appropriate items from the code. Selecting the last icon signifies that lateral buckling effects will not be considered during calculations.

To determine lateral buckling conditions, it is necessary, as well, to specify a value of the moment distribution coefficient.

Lateral buckling calculations require defining for a member - the distance between sections protected against torsion - so called lateral buckling length. It is necessary to distinguish two buckling lengths (for the upper and for the lower flange) as it is possible to fix the upper and lower flanges separately and there may occur compressive stresses in different load cases in the upper or lower flange. Therefore, the user should provide a value of the coefficient by which the base member length should be multiplied to obtain the lateral buckling length. The length Iz is assumed to be the base length. The coefficient value may be entered directly or by selecting the icon representing typical attachment case for which the coefficient will be automatically chosen (see: effective length of beams and effective length of cantilever.

Once the More button is pressed, the additional dialog box appears on the screen where the user may define the remaining member type parameters described in the code such as: equivalent moment factor, section parameters, etc.

After pressing the Service button, the additional dialog box opens on the screen, in which parameters of member type (limit displacements, camber) may be defined.

Once the Stiffeners button is pressed, the additional dialog box is displayed on the screen, in which the user may define stiffeners (transverse stiffeners) along the member length.

Pressing the Save button results in adding the member type with a defined name and determined parameters to the list of previously defined steel member types