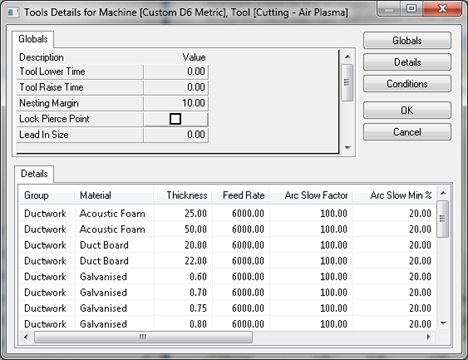

Using the Tool Details for Machine dialog, you can define a set of values to the tools associated with installed machines. This can be done either globally, or this can be dependant on material and gauge details. The settings will differ slightly from controller to controller, but some of the main ones are listed below.

To access these tool settings, on the Tool Details for Machine dialog, click Globals to access global settings, or Details.

Edge Approach: This is used when Rip Cutting and determines the distance from the edge of the material that the rip will start and end. This will effectively apply a stitch to the ends of the cut.

Pierce Size: The figure in here will be the minimum size of hole the tool-head will cut. Any hole below this value will be pierced i.e. entering 5 in this box will state that any hole less than 5mm will be pierced, anything over 5 mm will be cut as a small circle.

Arc Slow Radius: The number in here is the minimum radius of a cut before the torch will slow down.

Arc Slow Factor: This determines the speed at which the torch will slow down. 100 would be normal slowdown, 200 would slowdown twice as fast. Used mainly on Cybermation machines. If the slow down is not happening quickly enough it is recommended that an Arc Slow Factor of 500 and an Arc Slow Min % of 25 is used.

Arc Slow Min %: This is the percentage of the normal cutting speed that the slowdown will never go below.

Enable Pierce Delay: Enabling this option will make the tool-head delay slightly before moving to the next cutting point. This is useful when making lots of piercing in thin materials such as aluminium and prevents the cutting of "tear shaped" holes. The amount of delay is determined in the Pierce Delay option.

Height Control Lock Distance: Used in cutting torches that have height sensors. The value in here will lock the torch, at its current height, when it gets to that distance from the end of the cut. Stops Arc Sensor torches dropping into holes at the end of a cut.

Height Control Unlock Distance: Distance the torch has to travel from last cut before activating height sensors again.

Tool Lower Time: Time, in seconds, that it takes for the torch to lower.

Tool Raise Time: Time, in seconds, that it takes the torch to raise.

Feed Rate: Most feed rates are set within the controller but it is possible to set them within the Fabrication products. These are usually set at the Detail level where thickness and type of material will determine the speed of the cutting.

Kerf Value: This is the thickness of the cut produced by the cutting torch. This is important when cutting as the controller will move the head of the torch half this value to the inside or outside of the cutting line depending on the type of cut being produced.

Pierce Delay: This is the amount, in seconds, that the torch will delay before moving on to the next cut.

Number of Heads: This is used in multiple torch or bed set-ups and determines the number of torches attached to the cutting machine.

Mark Pierce: This will create a mark at the location of the pierce hole rather than cutting the actual pierce hole.

Suppress Feed Rate:With this button selected, the feed rate will be ignored by the controller. Used for reporting purposes only.

Lead In Size: This field allows to user to assign a Lead In specific to a Material and Thickness. This will then be applied if the Lead In, on the Lead In Style, is set to Auto. For more details on Lead Styles, see Leads.

Lead Out Size: This field allows to user to assign a Lead Out specific to a Material and Thickness. This will then be applied if the Lead Out, on the Lead Style, is set to Auto. For more details on Lead Styles, see Leads.