The tools associated with a machine can be customised to accommodate specific requirements of individual controllers. To access the dialog, Click File  Setup

Setup  Installed Machines or select the Installed Machines icon from the Utility Bar. The Installed Machines dialog displays.

Installed Machines or select the Installed Machines icon from the Utility Bar. The Installed Machines dialog displays.

Typically, only one machine name is displayed, and it is highlighted (selected) with a green circle next to it indicating this is the default machine. In cases where multiple machines are installed, only one machine at a time can have the green default machine icon.

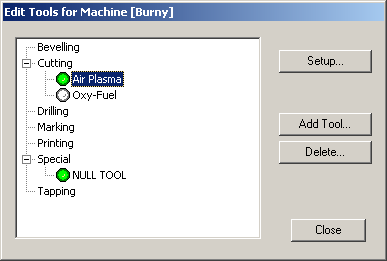

Click Tools to display the Edit Tools for Machine [Machine Name] dialog.

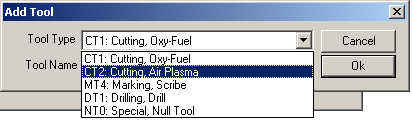

Highlight a tool (in the example above, the "Air Plasma" machine is highlighted) and click Setup. If there are no tools assigned, click Add Tool and choose a relevant tool from the drop-down list, as shown below.

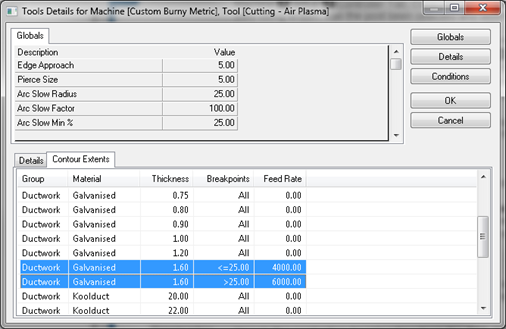

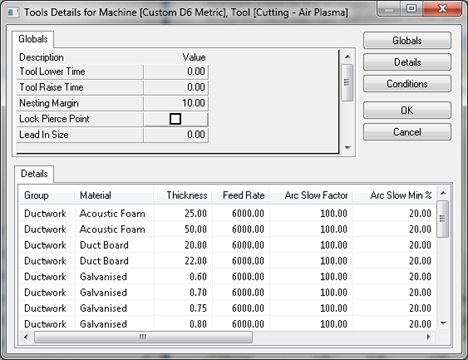

After clicking Setup for the tool, the Tool Details for Machine [Machine Name] dialog displays.

This dialog details the specific tool settings for all combinations of material and gauge that exist on your database. Some of the settings apply globally (for example, the "Pierce Size") whereas others differ with each material and gauge (for example, "Feed Rate"). For more information on these setting, Tool Settings.

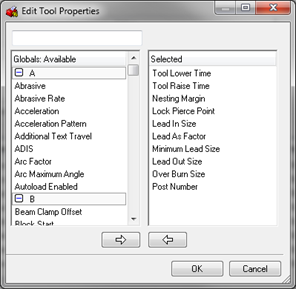

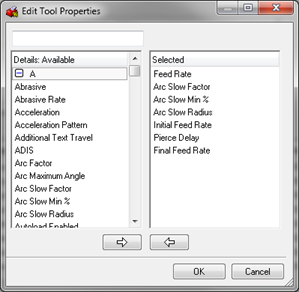

These 2 categories of settings are organized into the "Globals" and the "Details" tabs on this dialog. Clicking the Globals or Details button on the Tool Details dialog displays the relevant Edit Tool Properties dialog, as shown below. Global or Detail settings are added by dragging them into the "Selected" pane on the right, or removed by dragging them into the "Available" pane on the left.

To edit any of the global parameters, click in the field and change the value:

Pierce Size: This refers to a hole diameter. The cutting machine will pierce any hole that has a diameter less than or equal to the entered value.

Arc Slow Min: The % value is the minimum percentage that the machine will slow to when it comes to a radius less than or equal to the value in the Arc Slow Radius field. The machine will not drop to this minimum percentage speed instantly, and the drop is proportional to the size of the element.

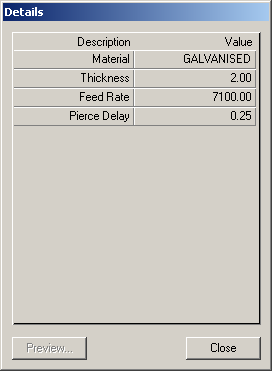

To alter any of the material detail entries, double-click anywhere on the row that you wish to change. The Details dialog displays:

Feed Rat:This value is in mm per minute for this material and gauge. On some controllers, the feed rate is defined within the controller and this value is treated as information only. If the Suppress Feed Rate option is chosen, either globally or at this detail level, the feed rates will not be written away to the NC data.

Pierce Delay:This is the time in seconds that it will take for the cutting tool to pierce a hole at this combination of material and gauge - i.e. the time that the torch will be stationary while the hole is cut.

Kerf Value: This caters for the thickness of the cutting tool. The value entered here is the width of material that will be removed by the cutting tool (from the Old English coerf - groove). Kerfing will be defined for the tool as to the left or the right, and works in conjunction with the cut side. See Tool Use for more information.

Conditions

It is also possible set conditions on some machine tools. This is accomplished by clicking the Conditions button, and adding the relevant condition. For more information, See Setting Conditions for Machine Tools.