In the Autodesk Fabrication products, ancillary items, such as flange materials, channel, corners, bolts, and gaskets, can be created and stored in the database for items to use and quantify automatically at takeoff. Ancillary items are items that you can add to other items (parts) so that you can apply or add more accurate costing, manufacturing, and installation time information to a part. It is important to understand, however, that In the Autodesk Fabrication products ancillaries have no graphical representation in the model. In other words, they do not display in the model.

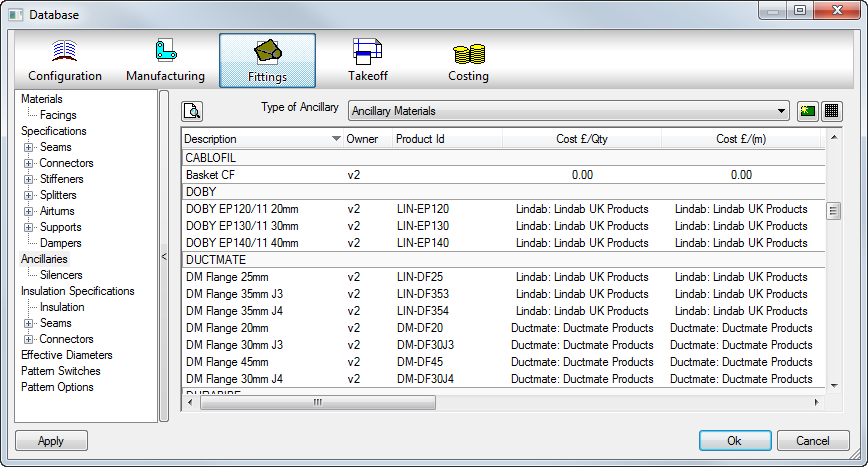

The cost and time information for ancillary items is defined in the Ancillary section of the database, under Fittings. Click Database

Fittings

Fittings

Ancillaries to access these settings.

Ancillaries to access these settings.

The principle is the same for other costed ancillaries, such as air turns and supports. The advantage of using this method is that a price list can be used more than once. This is more convenient when setting up similar items; for example, a Ductmate connector and a Ductmate stiffener. Both of these items can use the same corners, profiles and bolts, so the same price/time lists can be assigned to each.

Creating Ancillaries

The following pre-requisites should be considered before introducing a new ancillary into the database:

- Ancillary type: Decide which ancillary type best suits the ancillary. Note that the ancillary may not be available for selection when applying to the component. For example, creating a Fixing, and then attempting to apply it to the Clips section of the Connector database would not be possible. You would need to create the ancillary in the Clips section of the Ancillary database for it to be listed.

- Costing method: Another pre-requisite is to know how the ancillary will be costed. Will it be costed Per Quantity or Per Meter? On creation, values need to be entered in the per meter section, if it is a length-based ancillary (for example, gasket tapes, flange lengths), or per quantity for single units, such as fixings or clips. The alternative to entering a value on the ancillary itself is to enter a code, and then link to a price list for the cost. The cost can then be controlled from the price list, whether it is priced per meter or per quantity.

Click the

icon to create a new table entry, ensuring the type of ancillary has been selected first. Information on each field available for entry is listed below:

icon to create a new table entry, ensuring the type of ancillary has been selected first. Information on each field available for entry is listed below:

Description: A descriptive name for the ancillary. This can be letters or numbers.

Product ID: Lets you specify a supplier's product code or catalog number, typically used for referencing a price from a price list. The price list must contain this code and have a valid price assigned.

Cost £ /(Qty): A value entered which is the cost of the ancillary (per quantity). If using a price list, this field will be the price list name used that the product code exists inside. (Must have a product code and price in the price list set to "each").

Weight (kg)/Qty: The weight of each ancillary item, in kilograms.

F Time (mins)/Qty: The time required to manufacture one of the described ancillary items, in minutes.

E Time (mins)/Qty: The time required to install/erect one of the described ancillary items, in minutes.

Once the ancillary has been created, select Apply and OK to add the entries to the database. The Ancillary is now ready to be included into an Ancillary Kit or applied to the individual component (connector, seam, support, stiffener etc.)

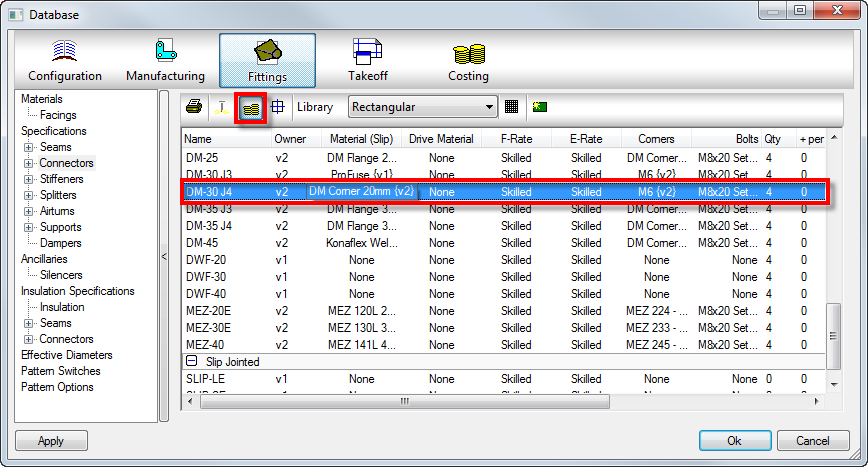

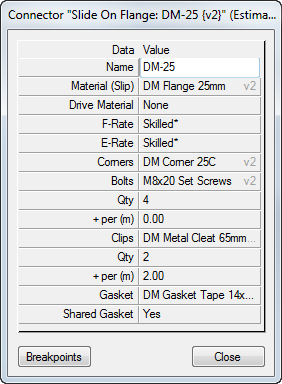

Accessing the Database, and then clicking the Costing tab

of the component allows selection of the ancillary.

of the component allows selection of the ancillary.

For more information, see Item Ancillaries and Creating Ancillaries.

Ancillary Kits for Support Rods

Ancillaries can also be configured to use ancillary kits for specifying support rod diameters. You may want to use this method of specifying support rods in situations where it is important to maintain updated costing data for supports. For more information, see Controlling Support Rod Diameter with Ancillary Kits