Ramp milling strategy

The Ramp toolpath creates a spiraling, helical cut around the model. It is best applied to steep areas and walls that are near vertical, similar to the Contour strategy.

The Ramp toolpath can be used for semi finishing and finishing. This strategy ramps down the walls a specified Z distance, for every complete revolution around the model. This ensures that the tool is engaged at all times. A technique that can be important for brittle materials that chip.

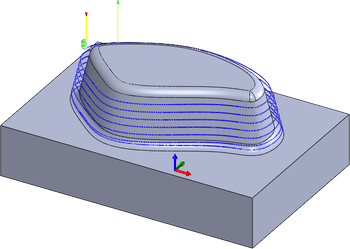

Ramp toolpath on the outer walls.

The Minimum Diameter and Minimum Cutting Radius parameters can be used to avoid binding of the tool in tight corners. The Maximum Stepdown parameter controls the steps in Z. Lead & Transition parameters control blending onto the start and off the end of the cut.

You can use Machining Boundaries to contain the machining area in X & Y and the Heights parameters to contain the machining areas in Z.