Testing post processors

If you are testing a new post processor, post process and run one operation at a time. This way, it is easier to fix code problems. You can test a post processor with the Post Processor Benchmark test files.

How to know which post processor will work with your machine?

You need to test a post processor by creating a sample program, or using sample toolpaths, or Post Benchmark test files.

Create a sample program

Create a sample program that demonstrates key functions. The first part to cycle on your machine should not be the part you need to make. It is probably not going to test all the functions for your CNC control.

Use sample toolpaths

Access the sample toolpaths from the Fusion Data Panel by selecting CAM Samples > Post Processor.

The Post Processor folder contains test files for milling and turning.

Select the appropriate sample file, based on the type of machining and the units you will be working with.

Select the post processor that you think best matches your machine/control combination and create the CNC code.

If you experience errors at your machine, you may want to post process one operation at a time to simplify the debugging process.

Use Post Benchmark Test Files

Access the Benchmark Test Files from the Fusion Data Panel by selecting CAM Samples > Post Processor:

- Milling_INCH - Post Processor Benchmark

- Milling_MM - Post Processor Benchmark

- MillTurn_INCH - Post Processor Benchmark

- MillTurn_MM - Post Processor Benchmark

Testing the post processed NC code

Load the benchmark NC code into your machine.

Set your offsets to a safe position and dry cycle the machine.

Dry cycle means to run the program without cutting tools.

If the machine stops and reports any errors, you need to figure out what is wrong with the NC code. You can try using a different post processor and run the new NC code.

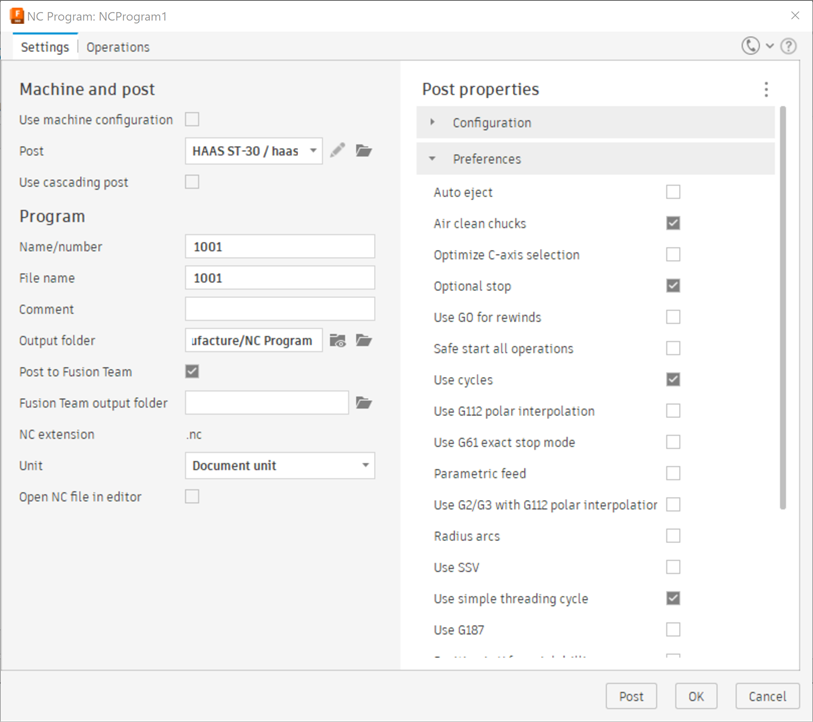

If you find a problem with the code, check the Post Properties in the NC Program dialog to add or remove functions. If a post processor does not seem to be right for your machine, you may have turned on or off an option that is affecting the output. Properties can vary depending on a post processor.

The NC Program dialog.

Still experiencing errors?

If you still experience any errors, follow these steps:

Write down the complete error description and any error numbers.

Note the line number where it stopped or reported the error.

Check your machine manual to find the error explanation

Compare the error, to the line of code where the program stopped.

Investigate what the machine/control expects to see.

Review the machines programming manual for the function of the NC code that caused the error. You can also send the the program to the machinery company with the information about the settings in the NC Program dialog.

Once you find the correct format for that line of code, modify the NC program and run it again. Repeat this process until you get all the way through the program. Once you have completed this process, you have a program that works in your machine.

To modify a post processor, you need a sample program that has run on your machine.