Activity 6: Tap holes

In this activity, you duplicate the existing drilling toolpath and edit it to create a tapping toolpath. Tapping creates threaded holes in the part. It is similar to a drilling operation but uses a different type of cycle.

Prerequisites

- Activity 5 is complete.

Steps

Duplicate the Drill operation and rename it.

In the Browser, select the existing Drill operation.

Right-click and select Duplicate.

Double-click the new copy and change the name to Tapping M6.

Create and select a new tapping tool. Be sure to change Number to 8 on the Post Processor tab, change the type to (Tap Right Hand), with a diameter of 6 mm and a flute length of 15 mm. Set the spindle speed to 400 rpm.

In the Browser, right-click the Tapping M6 node and select Edit.

The Drill dialog opens.

On the Tool tab

, click Select.

, click Select.Click New tool

.

.On the New tool list, under Hole making, click Tap Right Hand.

On the Post Processor tab, set the tool Number to 8.

On the Cutter tab, set the Diameter to 6 mm.

Set the Flute length to 15 mm.

On the Cutting Data tab, set the Spindle Speed to 400 rpm.

Click Accept to create the tool.

Select the created tool and close the dialog tool by clicking Select.

Important: If you want to run this toolpath on your machine tool, you may also need to set the Thread pitch on the Cutter tab, and adjust the feed and speed parameters. The correct values can be found in the tool manufacturer's catalog.

Changing the cycle type to Tapping.

Click the Cycle tab

.

.Change the Cycle Type to Right Tapping.

Click OK to start the calculation.

Activity 6 summary

In this activity, you copied the existing drilling toolpath and edited it to create the new tapping toolpath. This completes all the machining strategies for this part.

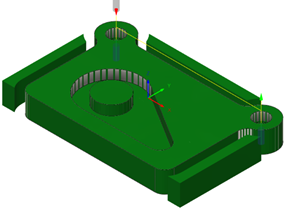

The calculated toolpath with in-process stock is shown below.

The toolpath is shown with a red arrow start, yellow rapid move, green lead-in and lead-out moves, blue cutting moves and a green arrow at the end.