Activity 5: Machine steep areas using contours

In this activity, you will use a Contour operation to machine the steep areas of the part. There remains between 0.2 mm and 0.4 mm of material left on the part (0.3 mm stock to leave plus/minus 0.1 mm tolerance). Several semi-finish operations will be used to reduce this material.

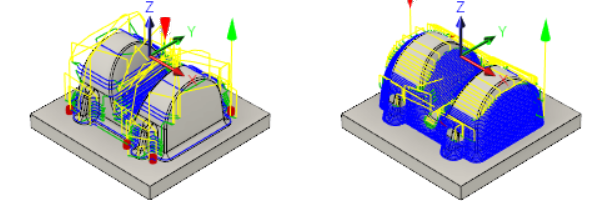

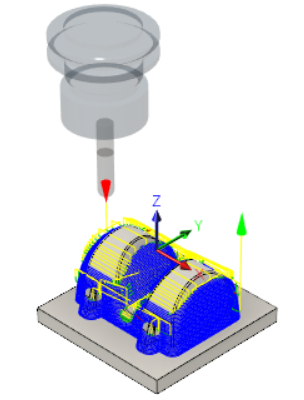

Part with 3D Pocket Clearing applied to it (left). Part after using Contour for Steep areas (right).

Prerequisites

- You have applied a 3D Pocket Clearing strategy to the part (Activity 4).

Steps

From the Contour dialog, select the #20 - Ø10 mm ball tool.

- On the Manufacture toolbar, Milling tab, select 3D > Contour

.

. - On the Tool tab

, click Select to access the tool library.

, click Select to access the tool library. - Select the tool 20 - Ø10 mm - ball from the Tutorial4 library.

- Click Select to close the Select Tool dialog.

- On the Manufacture toolbar, Milling tab, select 3D > Contour

Confine machining to steep areas only. This is achieved by limiting the slope range.

- Click the Geometry tab

.

. - From the Tool Containment drop-down menu, select Tool Center on Boundary.

- Enable the Slope checkbox.

- Set From Slope Angle to 60 deg.

- Set To Slope Angle to 90 deg.

- Click the Geometry tab

Specify the machining passes parameters.

- Click the Passes tab

.

. - Set Tolerance to 0.02 mm.

- Set Maximum Stepdown to 1 mm.

- Enable the Order by Depth checkbox.

- Enable the Stock to Leave checkbox. Use the default values of 0.1mm for this operation.

- Click the Passes tab

Specify the movements between passes.

- Click the Linking tab

.

. - Select Minimum Retraction from the Retraction Policy drop-down menu.

- Set Maximum Stay-Down Distance to 10 mm.

- In the Ramp group, set Ramping Angle (deg) to 10 deg.

- Click OK to automatically start calculating the toolpath. A preview appears on the canvas.

- Click the Linking tab

Activity 5 summary

In this activity, you used a 3D Pocket Clearing strategy to remove more of the remaining material where the 20 mm tool from the previous operation could not reach.