Activity 6: Machine shallow areas using scallop

In this activity, you will create a constant scallop toolpath to machine shallow areas of the boss.

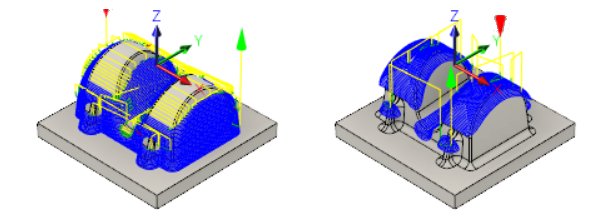

Part with Contour applied to steep areas (left). Part after using Scallop for shallow areas (right).

Prerequisites

- You have applied a Contour strategy to machine steep areas of the part (Activity 5).

Steps

On the Manufacture toolbar, Milling tab, select 3D > Scallop

.Note: The previous tool 20 - Ø10 mm - ball should still be selected. Leave all other settings on the Tool tab

.Note: The previous tool 20 - Ø10 mm - ball should still be selected. Leave all other settings on the Tool tab unchanged.

unchanged.Confine machining to shallow areas only. This is achieved by limiting the slope range.

Click the Geometry tab

.

.Enable the Slope checkbox.

Set From Slope Angle to 0 deg.

Set To Slope Angle to 65 deg.

Note: Machining from 0 degrees (horizontal) to 65 degrees from horizontal ensures that there is no excess material in the transition zone between this operation and the previous operation on steep areas, and that the tool starts in areas that are already machined. The set slope angle also includes the flat face at the base of the part, but this is finished later with 0 stock to leave using a Horizontal finishing strategy. To avoid machining the flat base of the part you can select it as an avoid surface. To learn more, please refer to About Avoid Surfaces.

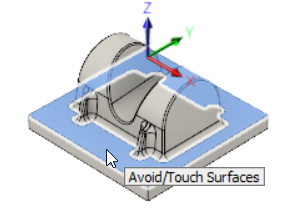

Avoid machining the flat base of the part.

- Enable the Avoid/Touch Surfaces checkbox.

- Activate the Avoid/Touch Surfaces button and select the flat face at the base of the part as shown in the following image:

Specify the machining passes parameters.

- Click the Passes tab

.

. - Change Tolerance to 0.02 mm.

- Change Stepover to 1 mm.

- Enable the Stock to Leave checkbox. Once again, use the default values of 0.1 mm.

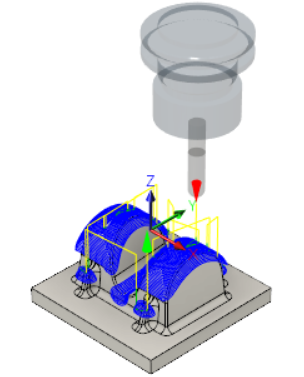

- Click OK to automatically start calculating the toolpath. The toolpath is now calculated, and a preview appears on the canvas.

- Click the Passes tab

Activity 6 summary

In this activity, you used a Scallop strategy to machine shallow areas of the boss.