Activity 8: Parallel finishing

In this activity, we will use the Parallel strategy to cut equally spaced rows, inside the machining boundary.

The cuts are parallel in the machining plane and follow the surface up or down, in the Z direction. Parallel passes are best suited for the finishing of shallow areas and down milling cuts.

Prerequisites

- Activity 7 is complete.

Steps

Start a new 3D Parallel operation and verify that Tool #21 - Ø6 mm R3 mm ball, is still the active tool.

- On the Manufacture toolbar, Milling tab, select 3D > Parallel

.

. - Select the Tool tab

- Be sure Tool #21 - Ø6 mm R3 mm (Ball end mill) is still the active tool.

- On the Manufacture toolbar, Milling tab, select 3D > Parallel

Containment of the machining area and angled wall slope control.

In the 3D Parallel command palette, click the Geometry tab

.

.Enable the Slope checkbox.

Set To Slope Angle to 35 degrees. This will limit machinable faces that range from 0 deg. horizontal, to 35 deg. vertical. Since the last toolpath was from 30 to 90, this provides a 5 degree overlap between the toolpaths.

Enable the Avoid/Touch Surfaces checkbox. Make sure that the Avoid/Touch Surfaces button is active.

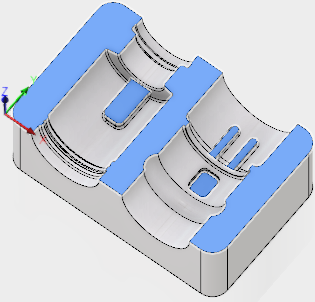

Select all of the flat faces as shown in the image below

Limit the toolpath area to cut below the Top.

- Click the Heights tab

.

. - The Top height drop-down list should be set to Model Top.

- Set the Top height Offset to -1 mm. Since we Face milled the top, this area is already machined. The Offset insures the toolpaths will start below the top face of the part.

- Click the Heights tab

Stepover cut value, cut angle.

- Click the Passes tab

.

. - Set Stepover to .2 mm.

- Set Pass direction to 45 degrees.

- Click the Passes tab

Controlling the rapid retract clearance method.

- Click the Linking tab

.

. - Set the Retraction Policy drop-down list to Minimum retraction.

- Set Safe Distance to 6 mm.

- In the Leads & Transitions group, set the Transition Type drop-down list to Straight line.

- Click OK to start the calculation.

- Click the Linking tab

Activity 8 summary

In this activity you selected a 3D Parallel finishing operation, created an overlapping toolpath area, contained the toolpath top and restricted the faces that can be machined.

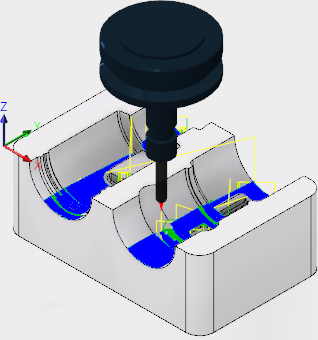

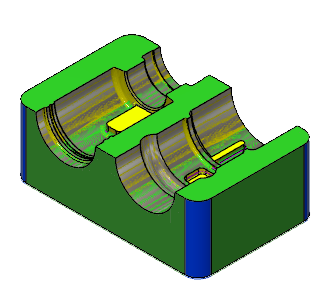

| The calculated toolpath is shown below. | The simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.