Activity 7: Cavity Contour

In this activity, we will start the finishing process with 3D Contour. This will finish the cavity walls.

Prerequisites

- Activity 6 is complete.

Steps

Start a new 3D Contour operation and, from the Tutorial Tools (Metric) library, select the #21 - Ø6 mm R3 mm ball tool.

- On the Manufacture toolbar, Milling tab, select 3D > Contour

.

. - On the Tool tab

, click Select. This opens the tool library.

, click Select. This opens the tool library. - In the Library, select Samples > Tutorial – Metric

- From the list, select #21 - Ø6 mm R3 mm (Ball end mill).

- Click Select.

- On the Manufacture toolbar, Milling tab, select 3D > Contour

Containment of the machining area and angled wall slope control.

- In the 3D Contour command palette, click the Geometry tab

.

. - From the Tool Containment drop-down list, select Tool center on boundary. This will keep the toolpath within the shadow edge boundary of the model.

- Set Additional Offset to 1 mm.

- Enable the Slope checkbox.

- Set From Slope Angle to 30 degrees.*. This will limit machinable faces that range from 30 deg. horizontal, to 90 deg. vertical.

- In the 3D Contour command palette, click the Geometry tab

Depth cut settings, flat area detection.

- Click the Passes tab

.

. - Set Maxiumum Stepdown to .3 mm.

- Disable the Flat area detection checkbox.

- Click the Passes tab

Controlling the rapid retract clearance method.

- Click the Linking tab

.

. - Set the Retraction Policy drop-down list to Minimum retraction.

- Set Safe Distance to 5 mm.

- Set Maximum Stay Down Distance to 8 mm.

- Click OK to start the calculation.

- Click the Linking tab

Activity 7 summary

In this activity you selected a 3D Contour finishing operation, selected a library tool, contained the toolpath, restricted the angle of the walls it will machine.

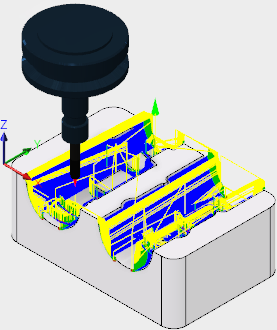

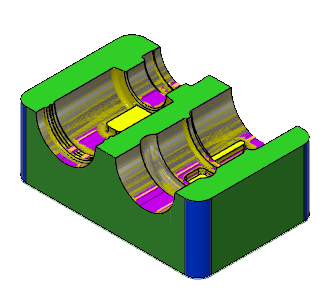

| The calculated toolpath is shown below. | The simulated toolpath is shown below. |

|

|

The toolpath is shown with a red arrow start, yellow rapid move, green lead in/out move, blue cutting moves and a green arrow at the end.