Activity 2: Using pocket clearing

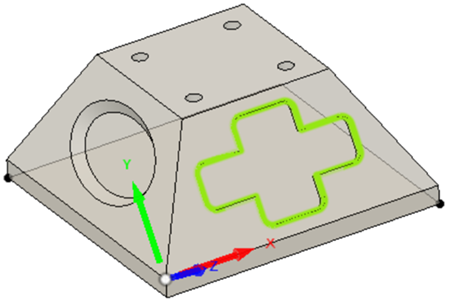

In this activity, you orient the part with a 3+2 machining setup and use an pocket clearing strategy to create the plus "+" shaped feature.

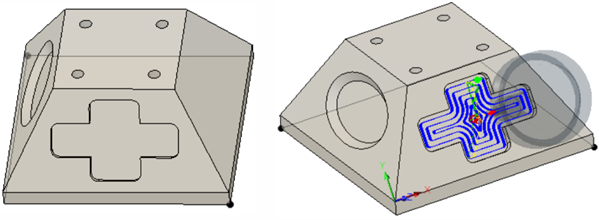

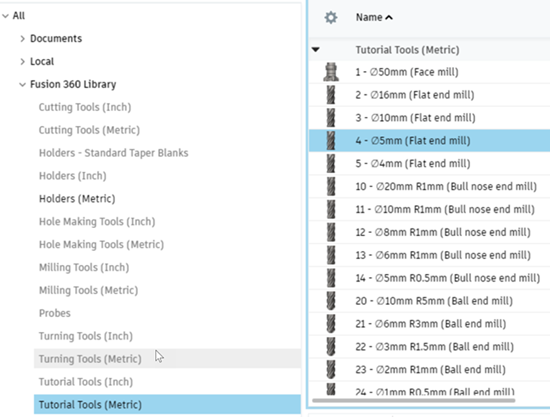

Before machining the part (left), after using pocket clearing (right).

Prerequisites

- Ensure the Tutorial3 model is open.

- Ensure the Workspace is Manufacture.

Steps

On the Manufacture toolbar, Milling tab, select 3D > Adaptive Clearing

.

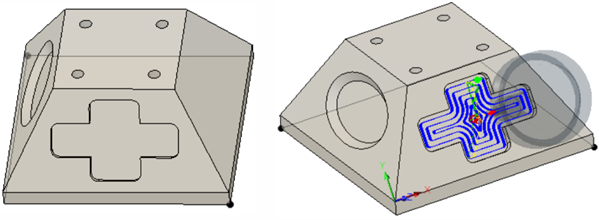

.In the Pocket Clearing dialog, set the tool to #4 – Ø5 mm (Flat end mill).

- Select

, Tool tab, on the pocket dialog, if not already selected.

, Tool tab, on the pocket dialog, if not already selected. - Click the Select button.

- In the Select Tool dialog, in the left panel, scroll to the bottom and select Tutorial Tools (Metric).

- In the list of tools, click the tool #4 – Ø5 mm (Flat end mill).

The Tutorial Tools (Metric) library is selected, then the specific tool is selected.

- Select

Click Select to select the tool and close the Select Tool dialog.

Define the orientation and the plus "+" geometry to machine.

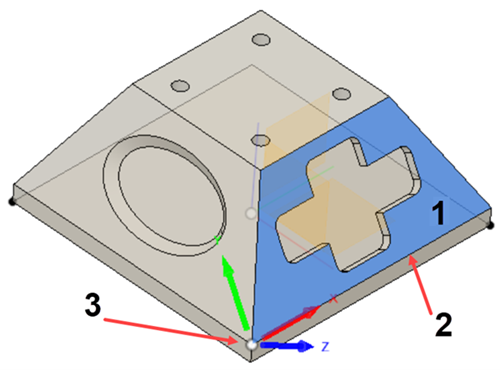

Plane defining the z axis direction (1), edge defining the direction of the X axis (2), corner defining the origin (3).- On the Pocket dialog, select

, Multi-Axis tab.

, Multi-Axis tab. - Check the Tool Orientation box, to expand this group.

- Choose Select Z axis/plane & X axis from the Orientation drop-down menu.

- Ensure the Z Axis button is active and select the face containing the plus, to define a face defining the Z-axis.

- Ensure the X Axis button is active and select the longest edge of the face you just selected. This selection defines the X direction.

- Choose Selected point from the Origin drop-down menu.

- Click the Point button for the Tool Orientation Origin parameter.

- Click the bottom left corner of the trapezoidal plane the ellipse is in to define the new origin.

- On the Pocket dialog, select

Pick the plus shaped edge as the machining boundary.

- Choose Selection in the Machining boundary perimeter.

- Ensure the Machining boundary selection is active.

- Click on the edge of the Plus shape.

- Click OK on the Pocket dialog to start calculating the tool path.

Before machining the part (left), after using pocket clearing (right).

Activity 2 summary

In this activity, you used a 3+2 machining technique to orient the part so the plane, containing the plus shape, is normal to the machine’s Z-axis. Then, you used pocket clearing to rough cut the plus shaped pocket.