Activity 7: Use Scallop for a finishing operation

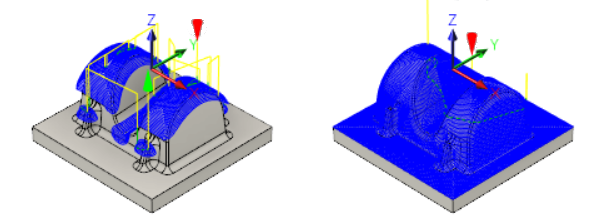

In this activity, you will use a Scallop strategy to finish the part. There is now 0.1 mm of remaining material on most of the part. There is a little more on top of the base surfaces, inside the 4 mm fillets, and on the lower part of the fillets at the base surfaces.

Part with Scallop applied for shallow areas (left). Part after using Scallop for finishing (right).

Prerequisites

- You have applied a Scallop strategy to machine shallow areas of the part (Activity 6).

Steps

From the Scallop dialog, Select the Ø6mm ball tool.

On the Manufacture toolbar, Milling tab, select 3D > Scallop

.

.On the Tool tab

, click Select to access the tool library.

, click Select to access the tool library.Select the tool 21 - Ø6 mm - ball from the Tutorial4 library.

Click Select to close the Select Tool dialog.

Note: The slope range was limited in the previous operations to confine machining to steep areas. In this operation we want to machine the entire part in one go to obtain a consistent amount of stock left. Machining is performed down to the flat area of the part, omitting the rectangular base.

Specify the machining passes.

- Click the Passes tab

.

. - Set Tolerance to 0.02 mm.

- Choose Inside -> Out from the Inside/Outside Direction drop-down menu.

- Set Stepover to 1 mm.

- Enable the Stock to Leave checkbox.

- Set Radial Stock to Leave to 0.05 mm.

- Set Axial Stock to Leave to 0.05 mm. This value should update automatically.

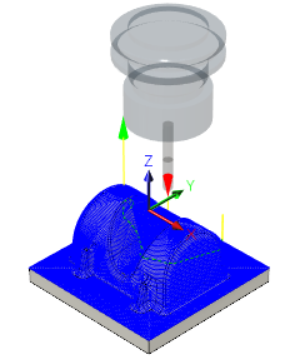

- Click OK to automatically start calculating the toolpath. A preview appears on the canvas.

- Click the Passes tab

Activity 7 summary

In this activity, you used a Scallop strategy as a finishing operation on the part.