Activity 9: Drill the four holes

In this activity, you repeat the Drill operation to create the four holes.

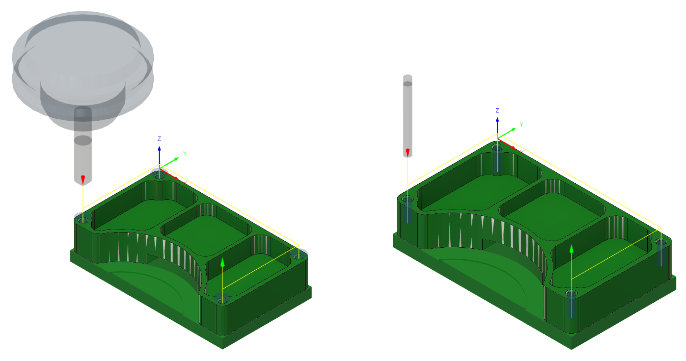

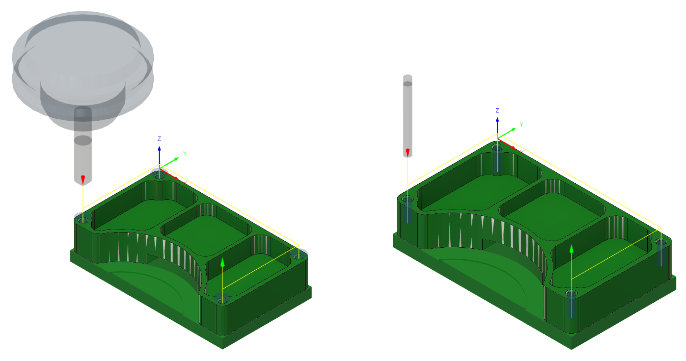

Before, showing the Drill toolpath applied at the conical faces of the four countersink holes (left). After, showing the Drill toolpath applied at the four holes (right).

Prerequisites

- Activity 8 is complete.

Steps

Select the 4 – Ø0.1065" 118° (#36) drill tool.

On the Manufacture toolbar, Milling tab, select Drilling > Drill

.

.On the Tool tab

, click Select to choose a new tool.

, click Select to choose a new tool.From the Documents > 2D Adaptive Milling Tutorial v1 list, select 4 – Ø0.1065" 118° (#36).

Click Select to close the Select Tool dialog.

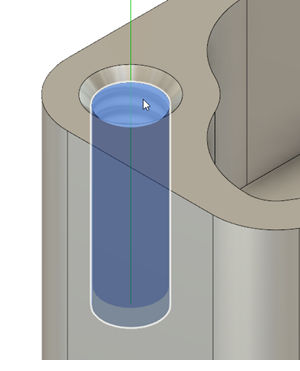

Select the inside face of any of the threaded holes.

Select the Geometry tab

.

.From the Selection Mode drop-down menu, confirm that Selected faces is selected.

Confirm that the Hole Faces button is active and select the inside face of one of the threaded holes.

Check the Select Same Diameter checkbox.

The other three threaded holes are automatically selected.

Enable Auto-Merge hole segments.

This ensures that the entire hole is included in the hole starting heights.

Set the drilling cycle type to Drilling – rapid out and start the calculation.

Select the Cycle tab

.

.From the Cycle Type drop-down menu, select Drilling – rapid out.

Click OK to create the toolpath.

Activity 9 summary

In this activity, you selected a tool and applied a Drill toolpath at the four threaded holes.

Before, showing the Drill toolpath applied at the conical faces of the four countersink holes (left). After, showing the Drill toolpath applied at the four holes (right).