Arrangement for additive manufacturing

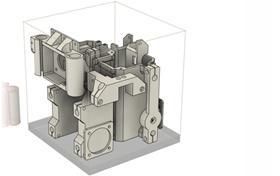

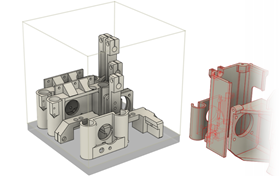

The Additive Arrange ![]() tool automatically arranges multiple components so that they fit inside an additive machine's build volume. Choose to arrange in 2D or 3D. Adjust the spacing options to refine the arrangement. If a component cannot be arranged, it is left outside the build volume and is highlighted red on the canvas.

tool automatically arranges multiple components so that they fit inside an additive machine's build volume. Choose to arrange in 2D or 3D. Adjust the spacing options to refine the arrangement. If a component cannot be arranged, it is left outside the build volume and is highlighted red on the canvas.

Arrangement types

You can choose from different methods for arranging components in 2D or 3D:

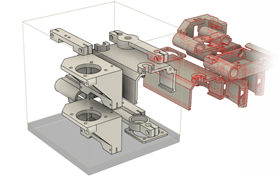

2D Arrange (True Shape) places components on a single layer on the build platform, making it ideal for when a single-layer arrangement is sufficient.

3D Arrange (Monte Carlo) uses a random sampling algorithm to generate samples and find the optimal arrangement of components. It aims to minimize the build height by efficiently filling gaps, making it suitable for complex and irregularly shaped components.

3D Arrange (True Shape) arranges components based on their true shapes, allowing for higher packing density and efficient use of the printer's build volume. It provides options for setting global quantities and rotation, making it ideal for maximizing space utilization and improving packing efficiency.