Post process for a live part alignment

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

After you have generated an Inspect Surface operation to inspect the surface of the part, post process it, along with all the other operations in the setup, to create NC code, which you can then run on the CNC machine.

In the Live Part Alignment contextual environment, click Post for Alignment

.

.The NC Program dialog opens.

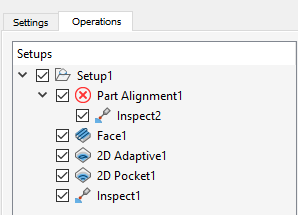

In the Operations tab, confirm that all the operations in the setup are selected.

Note: A red cross

Note: A red cross indicates that the part alignment has not been calculated yet.

indicates that the part alignment has not been calculated yet.(Optional) If you have multiple operations and want to group those that use the same probe or tool, select the Reorder to Minimize Tool Changes checkbox.

Complete the Settings tab, selecting an appropriate post processor that supports Inspect Surface capabilities.

Note: The parameters displayed depend on the selected post processor.In the Post Properties section, select the Live Device Connection checkbox.

Click Post.

An NC Program node is added to the Browser and a message is displayed when the file has been created.

Now transfer the NC code to the machine controller. When you run the NC code, import the inspection results in real-time using the live connection between Fusion and the CNC machine. If the calculated part alignment is approved, the NC code is automatically updated using the calculated part alignment.