Blend milling strategy

The Blend strategy performs finishing operations on steep or shallow areas between selected contours. It maintains a consistent cutting direction.

Using this strategy, you can machine complex geometry achieving surface finish of high quality. You can also detect and machine undercuts.

Geometry

The Blend strategy requires surfaces to guide creation of the toolpath. They are called Drive Surfaces. If you want to confine the toolpath to a smaller area within the drive surfaces, specify the Machining Boundary.

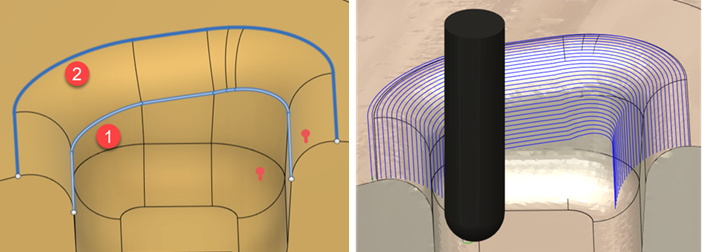

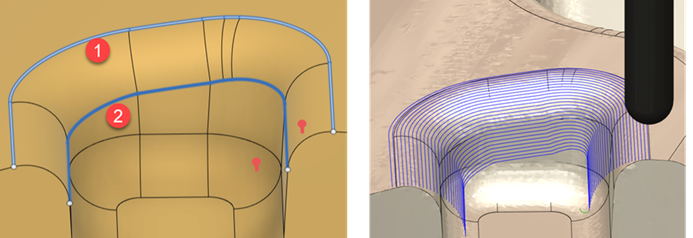

Drive curves

The strategy requires two drive curves to have better control over the toolpath. The order of selecting curves affects how the strategy creates the toolpath.

The bottom curve is selected first. The Blend toolpath starts at the bottom curve.

The top curve is selected first. The toolpath starts at the top curve.

Machining undercuts

You can detect and machine undercuts with a 3-axis toolpath after you:

Select suitable tools like lollipop mill, dovetail mill, or slot tool.

On the Passes tab, from the Stepover Calculation drop-down, select the On surface option. It calculates the stepover based on the surface of the part.