Geodesic milling strategy

The Geodesic strategy performs finishing operations to machine free-form surfaces and difficult undercuts.

A Geodesic toolpath consists of multiple passes arranged in patterns using different types of offsets.

Using this strategy, you can achieve smoother toolpaths with a higher quality of surface finish even in undercuts. Flexibility of defining machining boundaries, collision-free generation of toolpaths, and the capability to machine over holes improves the efficiency and quality of machining.

You can create 3-axis, 4-axis, and 5-axis geodesic toolpaths depending on your part geometry and capabilities of your machine. You require access to the Fusion Manufacturing Extension to create multi-axis toolpaths.

Geometry

The Geodesic strategy requires surfaces to guide creation of the toolpath. They are called Drive Surfaces. If you want to confine the toolpath to a smaller area within the drive surfaces, specify the Machining Boundary.

By default, Drive Surfaces are the Machining Boundary.

The arrangement of passes in the toolpath depends on the selected type of passes and how you offset the passes from the Machining Boundary.

Types of toolpath passes

Select one the following types of passes:

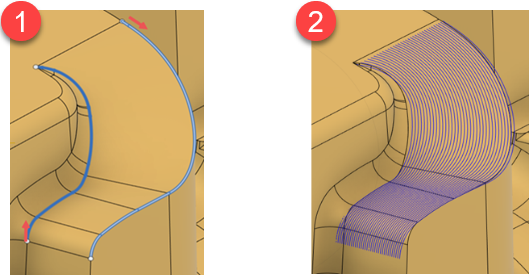

Blend - Requires two curves. The strategy creates a toolpath by offsetting these curves by a maximum stepover value. If the curves are not parallel to each other, the stepover may vary. You can select specific curves or the strategy can determine them based on the geometry. The toolpath is smooth and has fewer sharp corners.

Blend is useful for machining between two similar curves, such as fillets or chamfers. It enables blending a toolpath into surrounding regions or a specific machining boundary.

A Blend toolpath (2) created by offsetting passes from the two curves (1).

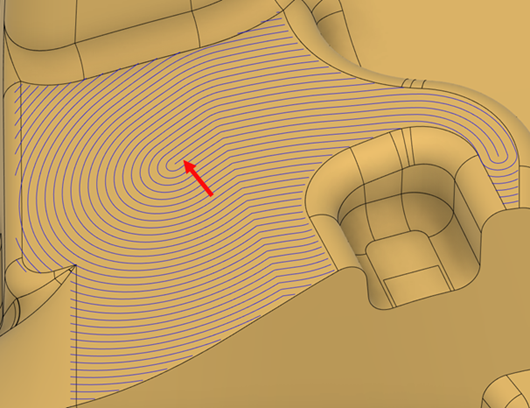

Note: Enable Smooth Stepovers on the Passes tab to add intermediate curves between drive curves. This option helps to create smoother, more adaptive stepovers that reduce sharp corners, improve surface finish, and produce a more even toolpath.Scallop - The strategy creates a toolpath by offsetting the passes by a constant stepover value. Depending on the boundaries to offset, the toolpath may have some sharp corners.

Useful for machining free-form surfaces, like the bottom of a pocket that has steep walls.

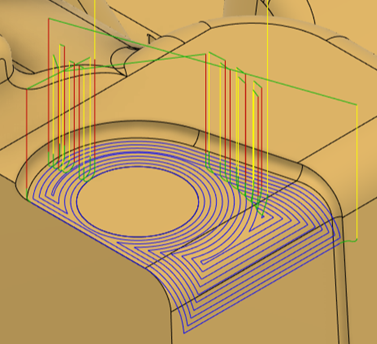

A Scallop toolpath created by offsetting passes from the line at the center.

Offsetting toolpath passes

You can arrange passes in different patterns depending on how you offset them. You can offset passes from:

- Machining Boundary

- Surface Boundary - The boundary of all the selected drive surfaces.

- Circle or a line at the center - A small circle or line near the center of the surface. The strategy determines their location.

- Curve selections - Two or more selected curves. The behavior differs depending on whether you use Scallop or Blend passes:

- With Scallop: The curves can be in any relation to each other. The offsets preserve each curve as far as possible until they clash, combine, or merge with others.

- With Blend: Select opposing curves (start and end curves). Each offset is a modified curve that transforms between the start and end curves, even when there is no clash. Intermediate curves control how that transformation happens, defining waypoints along the path.