Operation parameters overview

Parameters are individual options that influence how a toolpath behaves. Typically, parameters that relate to one another are grouped in tabs in the strategy dialogs.

Example of tabs in a dialog (milling)

Tool tab - Parameters relating to tool selection, coolant, and speeds and feeds.

Geometry tab - Parameters relating to selecting the geometry to machine.

Heights tab - Parameters relating to machining depths.

Passes tab - Parameters relating to the finer control over cutting moves.

Linking tab - Parameters relating to how the tool moves between cutting moves.

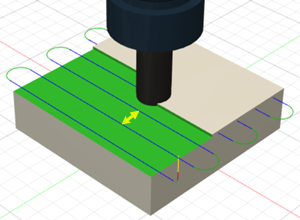

Parameter example - Stepover (milling)

In the Passes tab, a parameter that is common in most operations is the Stepover parameter, which specifies the horizontal distance between cutting moves in a toolpath.

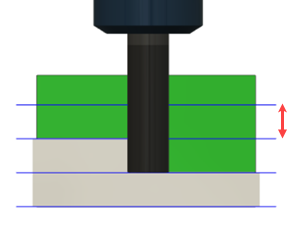

Parameter example - Stepdown (milling)

A parameter that is common in most operations is the Stepdown parameter, which specifies the vertical distance between cutting moves in a toolpath.