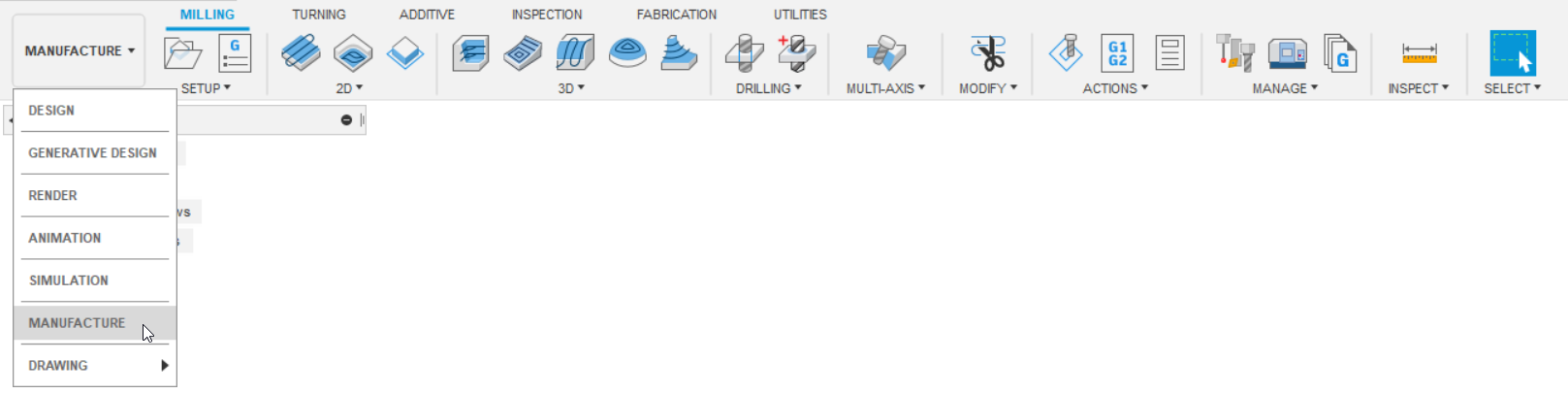

Manufacture overview

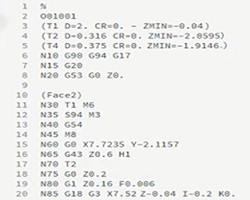

Use the Manufacture workspace inside Fusion to go from a design model to a programmed part that is ready for manufacture. Create operations and then post process them to get the required G-code that a machine can use to create a part.

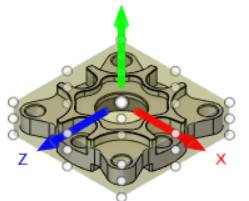

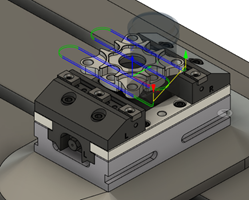

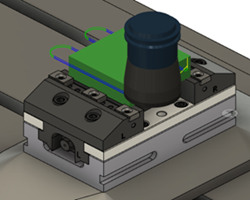

The workflow depends on the manufacturing process. Here is an example of a typical workflow when programming a part to be manufactured using CNC milling:

| 1) Create a design | 2) Create a setup | 3) Program the toolpaths |

|

|

|

| 4) Simulate the toolpaths | 5) Create the G-code | 6) Make the part |

|

|

|

Manufacturing processes

Fusion supports additive and subtractive manufacturing processes as well as inspection processes.

Types of processes currently supported by Fusion:

| Subtractive | Additive | Inspection |

|---|---|---|

| Milling | Fused filament fabrication (FFF) | Part setting |

| Turning | Stereolithography (SLA) / Digital light processing (DLP) | Part alignment |

| Drilling | Multi-jet fusion (MJF) | Geometric inspection |

| Water jet | Selective laser sintering (SLS) | Surface inspection |

| Laser cutting | Metal powder bed fusion (MPBF) | Manual inspection |

| Electron beam additive manufacturing (eBeam) | ||

| Binder jetting | ||

| Direct energy deposition (DED) |

Access the Manufacture workspace