Rest machining between setups

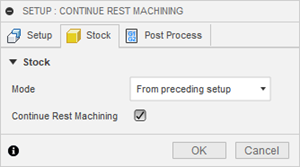

Continue Rest Machining between setups is a way to transfer stock from one setup to use on another setup. This is commonly done when you are machining the top side of a part on one setup, then machining its underside on another setup. The main benefit is that you get more accurate stock representation in the second setup, particularly during simulation. The stock transferring is achieved from the Setup dialog, using the From Preceding setup mode and the Continue Rest Machining checkbox options.

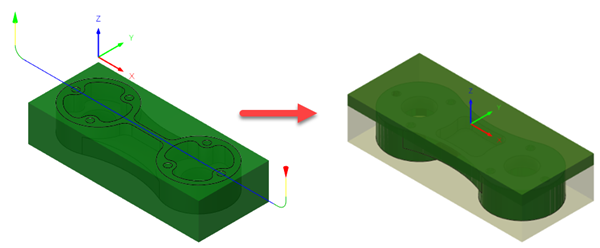

In the image below, the part on the left illustrates the first setup, machining the top-side of the part. The part on the right illustrates the second setup, machining the bottom-side of the part. The stock at the end of the first setup is used as the starting stock of the second setup.

How stock transferring works

For the stock to transfer accurately from one setup to another, both setups need to reference a single, identical component.

The reason why a single, identical component, and not body, needs to be referenced is because components contain bodies and origins. Geometrically, it is only possible to transfer the stock from one setup to another when the bodies can be referenced from their respective origins, all while being contained in a component.

Stock transfer between setups using STL files

You can also transfer stock from one setup to another by generating an STL file from the simulated result of the first setup. Watch the Create a setup in Fusion for turning video to see how it's done.

The STL method of stock transfer may be more suited to transferring stock between setups instead of Continue Rest Machining when:

The setup you are transferring stock from is not the preceding your current setup, and is higher up on the list in the browser. Note that Continue Rest Machining takes stock only from the setup that is directly preceding it in the browser.

You are transferring the stock from one document to another.

You need to manipulate the position of the stock before using it in the setup.