Tool orientation

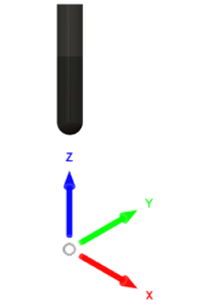

The tool orientation defines the cutting plane on a part. By default, the Z axis of the work coordinate system (WCS) that is defined in a setup sets the orientation of the tool.

You can override the tool orientation set by the WCS using the Tool Orientation group of settings. Using the Tool Orientation settings, you can change the cutting plane for when you need to manually orient a part in the vise to machine a different face.

If your machine has multi-axis capabilities, you can automatically rotate a part to machine a different face using 4th axis indexing, or you can fix two rotational axes in a position for 3+2 machining, referred to as 5-axis positional machining.

Tool always points down the specified Z axis.