Tool entry positions

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

You can move a tool's entry and exit position on closed toolpath passes without needing to recalculate the toolpath.

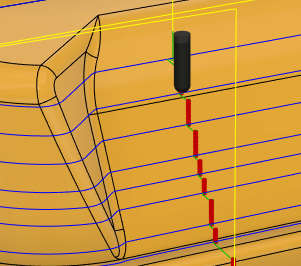

It is beneficial to control the tool's entry and exit positions because it helps avoid creating marks on the surface of the part. For example, marks are more visible on a part when the tool enters and exits each consecutive pass along the same vertical line.

To avoid this, the entry and exit positions can be staggered diagonally:

Having less visible marks on the part also reduces the need for manual polishing on the part after it has been machined.

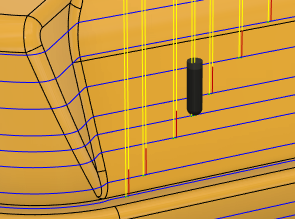

Another benefit of moving the entry and exit points is to avoid the tool from entering the machining area in where there is a very small gap between the clamp and the part.

The animation below shows how performing the modification recalculates the leads and links so the tool can enter at the positions selected by the sketched line.