Tutorial conclusion: Additive MJF

In this tutorial, you:

Opened the sample file containing the components.

Created an additive MJF setup and selected a printer.

Duplicated the components to ensure there are enough for an efficient print, maximizing the use of the printers’ build volume.

Arranged the components inside the printer’s build volume to optimize their placement and packing.

Checked the platform statistics to verify that the components are packed efficiently.

Filled the build volume with more components to use any remaining empty space, increasing productivity.

Checked the platform statistics again to confirm that the new arrangement is still optimized.

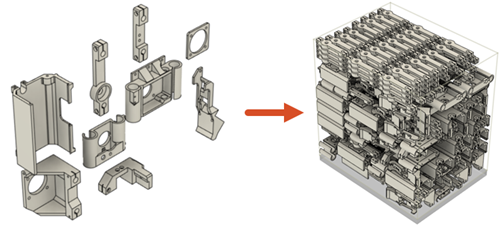

Components in the Design workspace (left), then duplicated and arranged in the HP Jet Fusion 5000 printer in the Manufacture workspace (right).