Turning Face strategy

A Turning Face strategy removes stock from the end of the part to produce a flat surface. The surface is perpendicular to the rotational axis of the part and is often used as a reference point for following operations.

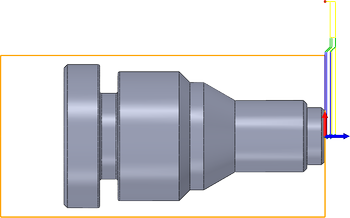

Turning Face taking several cuts off the front.

Geometry

You don't need to select geometry to generate a toolpath.

If needed, confine a toolpath within a specific region or extend it past the model for a longer cut. You can specify an offset, which is a distance to shift the toolpath boundary, relative to the Front geometry reference. Select it from the Front Mode drop-down list on the Geometry tab.

Facing direction

Depending on machining requirements, you can perform facing operation by moving the tool:

- Outside to inside - From the largest diameter toward the center of the part.

- Inside to outside - From the center toward the largest diameter. It is useful, for example, to machine tubes internally with a boring bar.

Number of toolpath passes

The number of cuts in the toolpath depends on the material, cutting tool, and required surface finish. By default, the toolpath includes one pass to remove bulk stock from the part.For finishing, to achieve the required surface finish and dimensional accuracy, specify multiple cuts. To do so, select the Multiple Passes checkbox on the Passes tab in the Face dialog. Then, you can also specify Finishing Passes.

For more information, watch the Fusion turning basics video.