Turning Groove strategy

The Turning Groove strategy removes stock to create a groove on the part. Grooves are narrow channels that come in different shapes and sizes depending on the requirements.

Modes

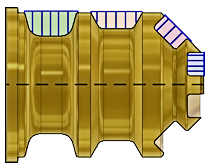

You can create grooves on the outside diameter (OD) of the part and the inside diameter (ID) of the part. It is called Outside grooving and Inside grooving, respectively.

By adjusting the Tool Orientation parameter, you can create grooves on angled areas.

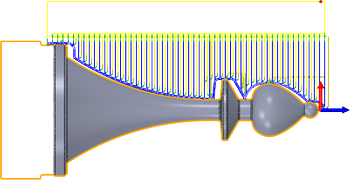

Turning Groove on the outside diameter, face, and angled area.

Roughing and finishing passes

The Turning Groove toolpath can include roughing and finishing cuts. Specify cuts on the Passes tab in the Groove dialog. For roughing, you can modify the Maximum Grooving Stepover value, depending on the material, tool cutting speed, and tool feedrate. The Maximum Grooving Stepover is the maximum distance that the tool moves axially in a single pass. If it is too large, it may result in poor surface finish and accuracy. If it is too small, it may cause tool damage.

Also, to help improve machining accuracy and surface finish, select the Use Pecking checkbox. While pecking, the tool makes several shallower cuts in the part. It is useful when machining deep grooves or hard materials.

For more information, watch the Turning groove video.