Turning Single Groove strategy

The Turning Single Groove strategy removes stock to create a groove at selected positions on the part. It creates a groove of the width equal to the groove width of the tool's insert. Useful for making a clearance groove behind the thread.

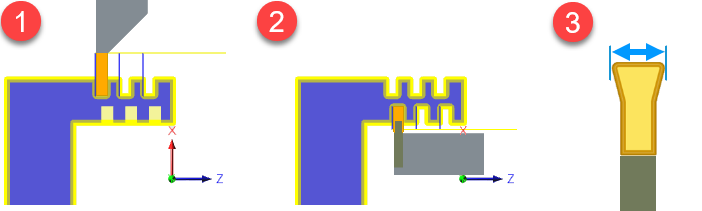

Turning Single Groove on the Outside Diameter (1) and on the Inside Diameter (2). Each groove's width is equal to the Groove width parameter of the tool's insert (3).

Modes

You can create grooves on the outside diameter (OD) of the part and the inside diameter (ID) of the part. It is called Outside grooving and Inside grooving, respectively.

By adjusting the Tool Orientation parameter, you can create grooves on angled areas.

Geometry

Specify Groove Positions by selecting an edge of each groove. You can machine one or more single grooves in a toolpath. By default, Fusion positions the tool's insert at the centerline of the groove geometry. To align the insert's position to one of the sides of the groove, change the Groove Side Alignment setting.

Passes

To help improve machining accuracy and surface finish, select the Use Pecking checkbox. While pecking, the tool makes several shallower cuts in the part. It is useful when machining deep grooves or hard materials.

For better chip evacuation, select Dwell Before Retract checkbox and specify Dwelling Period. It stops axial tool movements at the bottom of the groove, while the spindle keeps revolving. Dwells also help improve accuracy and consistency of machining.