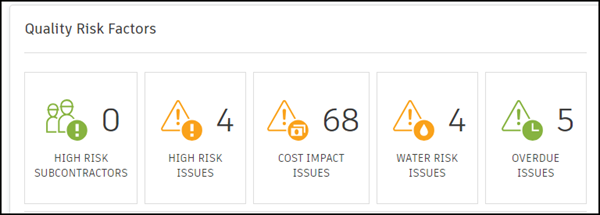

Analyze Quality Risk Factors

It is important to be able to quickly identify risk factors that might affect the quality or budget of a project. Construction IQ enables executives and project managers to assess project and subcontractor quality risks using the Quality Risk Factors card in the Risk feature.

The card summarizes the high-risk issues for the project, specific risk categories such as water issues, and high-risk subcontractors. It also includes overdue issues and checklist activity data.

You can click each factor in the card to view the issue and checklist data contributing to the predicted risk level.

For example, click the High Risk Issues factor to view a list of the project's high-risk issues. Click an issue's ID number to view its details, and change the risk level or category as needed. The card is automatically updated to reflect these changes.

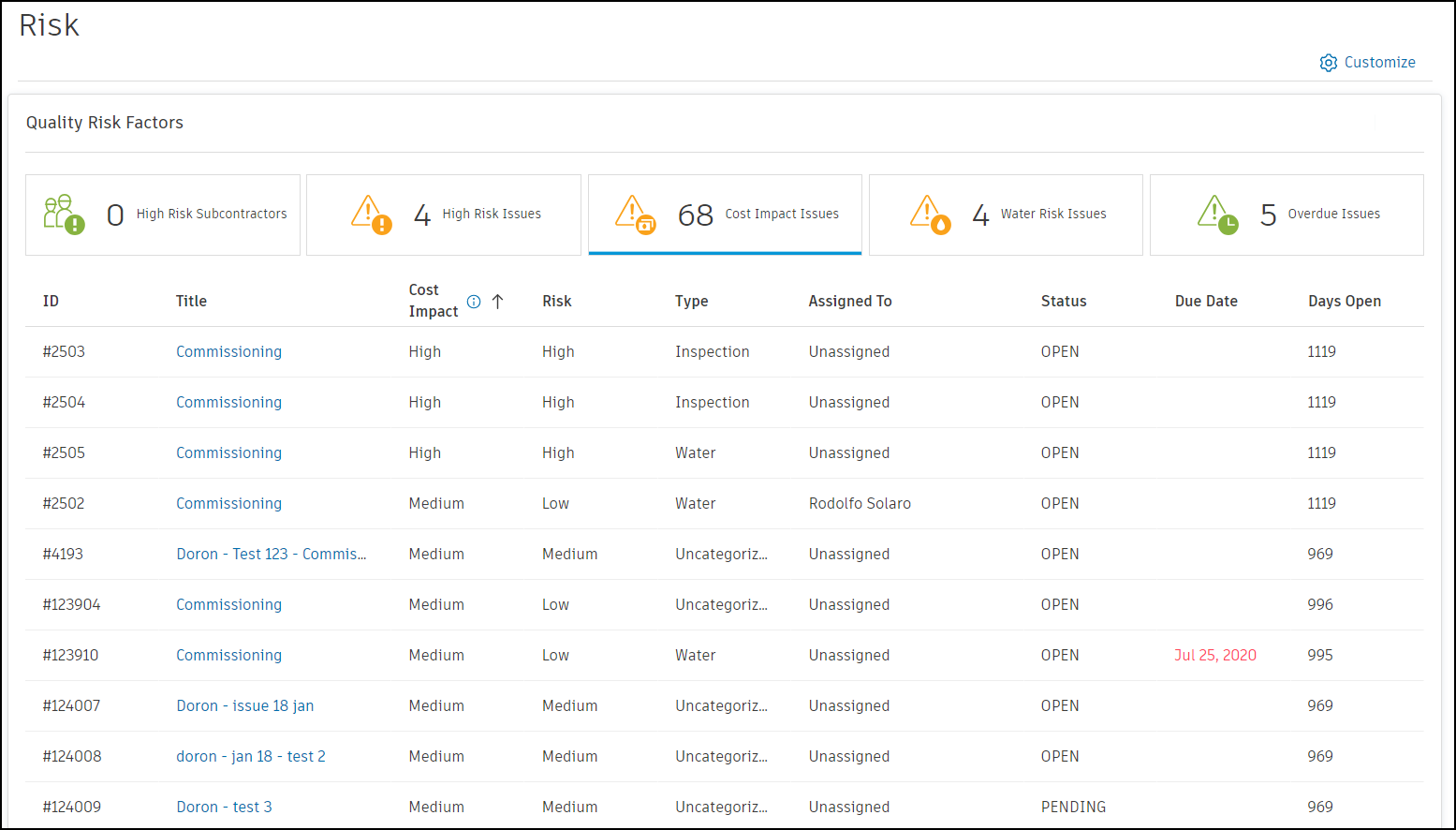

Cost Impact

Cost is an important aspect of any project. The Cost Impact Issues factor enables project managers to assess which open quality issues have the highest cost impact. They can then prioritize these issues to avoid going over budget (and possibly affecting project outcome).

Construction IQ reviews a project's quality issues, evaluating direct costs of materials, labor, and equipment, and indirect overhead costs, to estimate the overall cost to fix them.

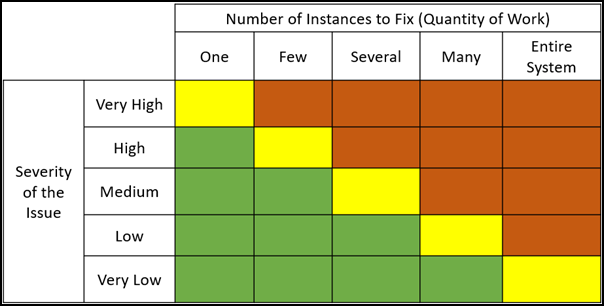

The issues are then ranked as high, medium, or low based on issue severity and the quantity of work required:

Green = Low, Orange = Medium, Red = High.

High-cost impact issues are critical issues that include expensive items or rework, long lead times that could affect schedule, major coordination problems, or water damage. They could take more than a week to address, and have the potential to significantly affect a project's budget. For example, a concrete compressive strength test failing to comply with the required standards, or a water leak resulting in the removal and replacement of drywall and insulation.

Medium-cost impact issues are moderate issues that require some rework, such as replacing an existing part, and are likely to take a few days to address. They may also be a low-cost issue occurring in several locations, or a single instance of a higher-cost issue. For example, replacing damaged ductwork insulation, or carrying out patch repairs of roof membrane.

Low-cost impact issues are minor issues that generally don't require expensive equipment or significant work hours to complete. They often affect only a single location, or include a small amount of rework. For example, providing circuit labels and junction box covers, or applying paint to a specific location.

Ranking issues based on cost impact helps project managers to plan and prioritize, ensuring work that could take longer and potentially cost more is addressed first.