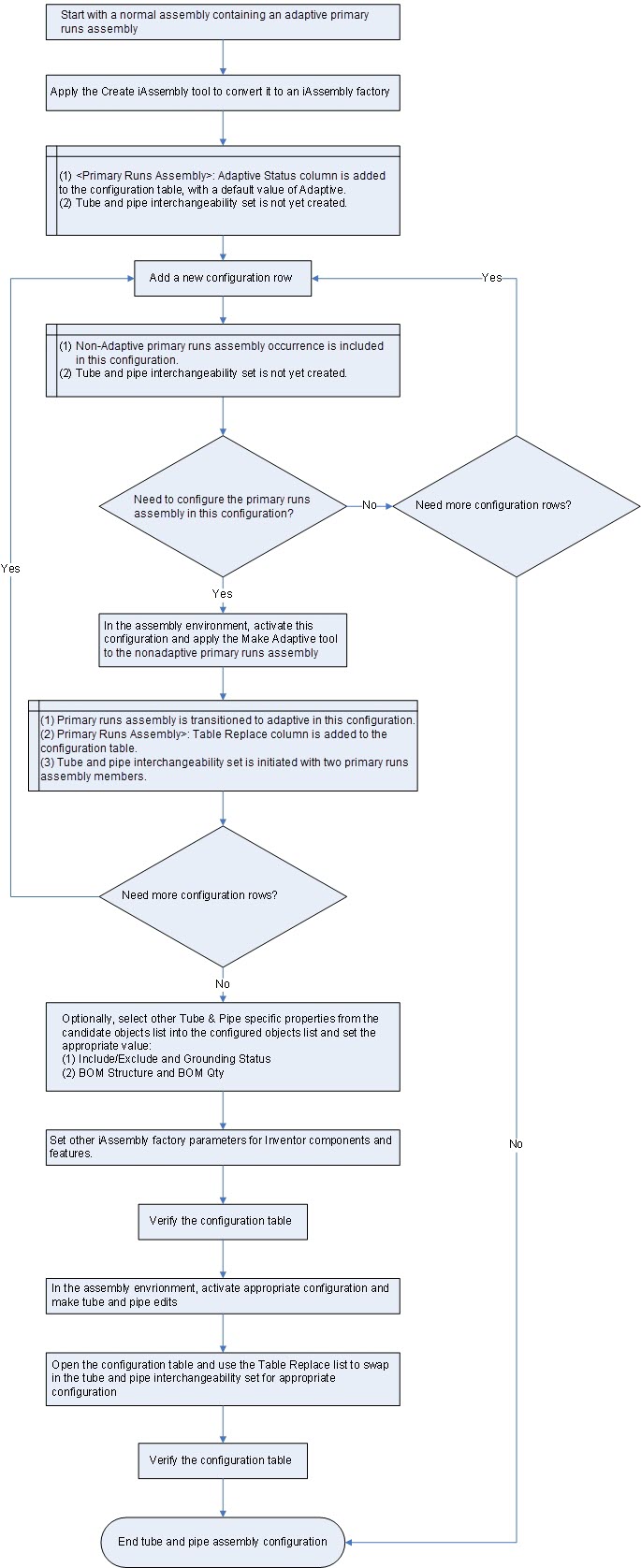

Use the Create iAssembly command to convert a normal Inventor assembly to an iAssembly factory. To configure the primary runs assembly for an appropriate configuration, create a tube and pipe interchangeability set and set specific iAssembly factory parameters, such as BOM. You can swap in the appropriate configuration and edit the tube and pipe design independently.

When a new configuration is added, the active configuration is the base for the new configuration and always remains active by default. The new configuration contains the same design content as the original except that the primary runs assembly becomes non-adaptive. To edit the tube and pipe content in one configuration independently, use the Make Adaptive command to transition it to adaptive. A new interchangeable configuration is created.

To create a tube and pipe iAssembly factory, you can start with either a normal Inventor assembly or a tube and pipe assembly. The workflows differ slightly. Typically the iAssembly factory starts with a tube and pipe assembly. If an iAssembly factory does not contain a primary runs assembly initially, you can add it later. The new primary runs assembly will be adaptive only in the active assembly configuration and remain non-adaptive in all other configuration members. Change the adaptive status and edit routes and runs in the appropriate configuration as needed. After the primary runs assembly is added, the workflow is the same as when you start with a tube and pipe assembly.

The following flowchart illustrates a generic workflow of creating a tube and pipe iAssembly factory and editing its tube and pipe interchangeability set.