Preconditioning analysis for reactive compression molding

The Preconditioning analysis calculates the change in the temperature and cure, once a thermoset resin is placed in the mold but before molding starts.

The existing preconditioning analysis for compression molding was developed for microchip encapsulation in the transfer molding, and assumes cylindrical pot geometry. It uses analytical solutions to calculate temperature change, and the results only show the average temperature and cure at the end of preconditioning. This preconditioning analysis is still used for all reactive molding processes other than reactive compression molding.

The Preconditioning analysis for reactive compression molding uses a numerical solution to calculate temperature and cure changes. During the analysis, only temperature and cure equations are solved; pressure-velocity equations are not solved.

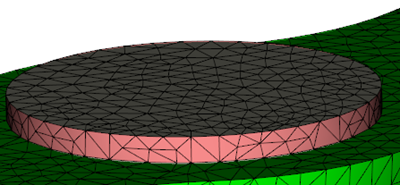

This feature is supported for reactive compression molding using the following mesh type:

3D

3D

Workflow

To run the preconditioning analysis for compression molding, preconditioning data is required. The data is specified either in the process settings or, if the solution is inadequate, you can enter local data on the elements themselves. When you specify the data in the process settings, contact conditions are used to automatically apply temperature boundary conditions.

- Click

(Home tab > Molding Process Setup panel > Process Settings).

(Home tab > Molding Process Setup panel > Process Settings). - Click Next, if necessary, until you reach the page with the Preconditioning analysis option.

- From the Preconditioning analysis drop down menu, select Perform preconditioning analysis

- Click Edit data

- Enter data in all the elements in the Preconditioning data dialog, then click OK.

- Click Next until you reach the final page of the Process Settings Wizard, then click Finish.

When the automatic assignment of preconditioning data is not appropriate, select specific elements and apply different thermal boundary conditions to them.

Results

The results show the temperature and cure distribution at the end of preconditioning. Look at the log file, to see the actual numbers. The preconditioning stage of the analysis is shown in negative numbers from - (delay time) to 0.

To understand the temperature and the degree of cure at the end of preconditioning, study the first time step of the Temperature result and the Conversion at node result. The results that correspond to the end of preconditioning are at, or close to time=0.