Troubleshooting mold hot spots

Mold surface temperatures are influenced by the position of the cooling lines relative to the surface of the mold. For simple parts of constant thickness, a uniform spacing of cooling channels gives uniform cooling.

However, most parts will vary in thickness, and geometrical features such as corners and ribs can lead to hot spots. Redesigning the geometry of the mold or varying the injection locations may help reduce hot spots.

In these cases it may be necessary to move cooling channels closer to the thicker areas, ribs or corners. Alternatively additional channels may be required.

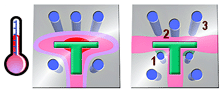

These concepts are illustrated in the images below.

Figure 1 Cooling channel layout

The left and right diagrams show the original and revised cooling channel configurations respectively. Zone 1 Extra channels are included and placed as close as possible to the surface of the mold, Zone 2 The cooling channel is moved closer to account for the extra heat load coming from the rib, Zone 3 It may be necessary to move the left and right channels away from the surface, though this is not shown.