Flexible initial charge for compression molding

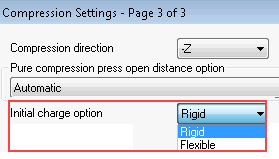

This compression molding enhancement enables you to simulate the behavior of either a Rigid or a Flexible initial charge.

Compression molding, and therefore this compression molding enhancement, is supported for the following mesh types:

3D

3D

In previous releases, the initial charge was assumed to be rigid and there was no option for a flexible initial charge. Now, you can indicate whether it is Rigid and maintains its original shape before the start of compression, or if it is Flexible and conforms to the mold cavity geometry, before compression starts. Rigid is set by default.

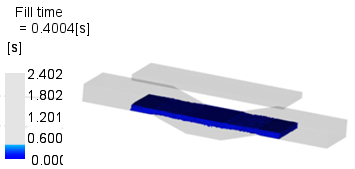

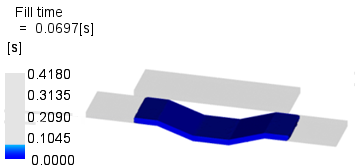

Set up the analysis as you did previously, with a part mesh and an initial charge mesh. Then set up the Process Settings, choose whether the initial charge is rigid or flexible, and run the analysis. For a rigid initial charge, the first step of the fill time result shows the initial charge in its modeled shape. For a flexible initial charge, the first step of the fill time result shows the initial charge draped in the part cavity, and following the shape of the part.

How closely the initial charge follows the bottom surface of the cavity depends on both the part geometry and the mesh density of both the part and the initial charge. Increase the mesh density to improve the draping, but remember that the analysis time increases with increasing mesh density.

(a) Rigid initial charge

(b) Flexible initial charge

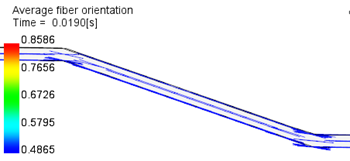

Fiber orientation results for a flexible initial charge

When you specify a flexible initial charge, and select a fiber filled material, the initial fiber orientation changes in accordance with the deformation. Use the Initial charge (3D) dialog to assign the initial fiber orientation in the global coordinate system.

To generate fiber orientation results, select a fiber filled material, and confirm in the Fiber/Filler tab of the materials database that the Aspect ratio (L/D) does not equal 1.