*PLAS

i1

r11, r12, r13, r14, ..., r1n,

r21, r22, r23, r24, ..., r2n,

...

n=2*i1+1

i1: i*4: number of (yield strength, equivalent plastic strain) points

r11: r*8: Yield strength for equivalent plastic strain r12 at temperature r1n

...

r13: r*8: Yield strength for equivalent plastic strain r14 at temperature r1n

...

- Isotropic plastic hardening is assumed.

- r12, r22, r32,.. should be zero.

- Perfect plasticity is assumed beyond the last (yield strength, equivalent plastic strain) point.

- If i1=1, the response is elastic-perfectly plastic (no hardening).

Refer to the Units of Measure topic for questions about the units to use for the yield strength.

Best Practices: Unless *PPLA is used, do not include *PLAS in Part-Scale Powder-Bed Simulations, as this behavior is already accounted for in the PRM generation phase and will incur lack of convergence. When performing part-level plasticity analyses using *PPLA, ensure there are *PLAS values assigned to the build plate properties as well, if a separate build plate *MATE and *MATI are used.

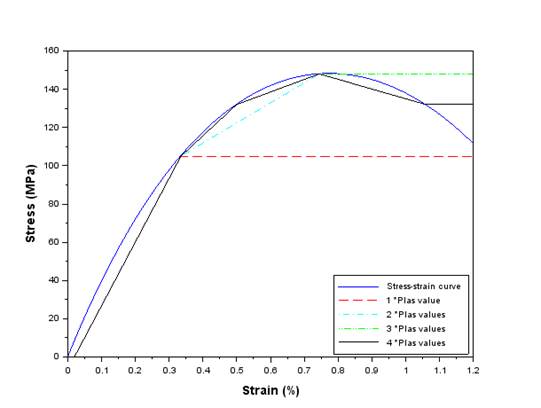

The following graph shows an example of fitting a stress-strain curve using the *PLAS card using 1-4 values. Using just 1 value assumes perfectly plastic behavior. Using 2 points along the stress strain curve will create a bilinear map of plastic properties, one line between the yield point and the second point, and then a region of perfect plasticity extending from the second point. This is the most common method to model the plastic behavior, and has been shown to be effective for various metals. Additional points may be used to further describe the stress-strain curve as desired by the end user. The more detailed the stress-strain behavior is defined in the mechanical model, the slower the convergence will be each step.

Approximating the stress-strain curve using 1-4 values in the *PLAS card