In this task, we select materials and material properties for the three parts of this assembly, apply physical properties (idealizations) to the parts, and mesh the model.

To define materials

- In the Model tree, right-click .

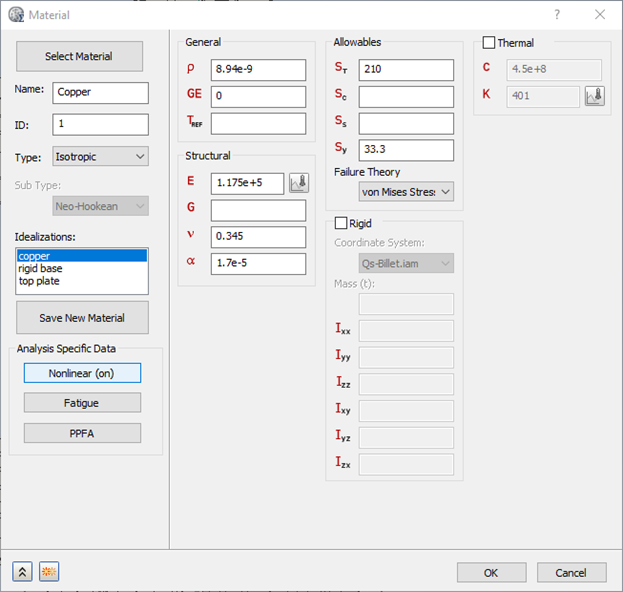

- In the Material dialog, click Select Material. The Material DB dialog will show some available material libraries.

- Expand the

Autodesk Material Library, select

Copper, and click

OK. This material will be chosen for the Billet.

- Click the Nonlinear button, then in the Nonlinear Material Data dialog select Elasto-Plastic (Bi-Linear). Click OK in this dialog and OK to close the Material dialog.

- In the Model tree, right-click again.

- In the Material dialog, click Select Material, expand the Autodesk Material Library, select Alloy Steel, and in the Material dialog, rename it to Alloy Steel_Base Rigid.

- In the third column of the Material dialog, select Rigid. Doing this tells the analysis code to treat the bottom base plate part as a rigid body. The code will compute the center of mass and inertial properties of the part.

- In the lower left corner of the

Material dialog, click the Duplicate

button. The Alloy Steel_Rigid Base material is added to the model, and the Material dialog remains open for definition of a third material.

button. The Alloy Steel_Rigid Base material is added to the model, and the Material dialog remains open for definition of a third material.

- Click Select Material, expand the Autodesk Material Library, and again select Alloy Steel.

- In the Material dialog, rename the material to Alloy Steel_Top Plate, and deselect the Rigid option.

- Click OK to close the dialog.

To define idealizations

- In the Model tree, under Idealizations, delete any existing Solid materials, then right-click .

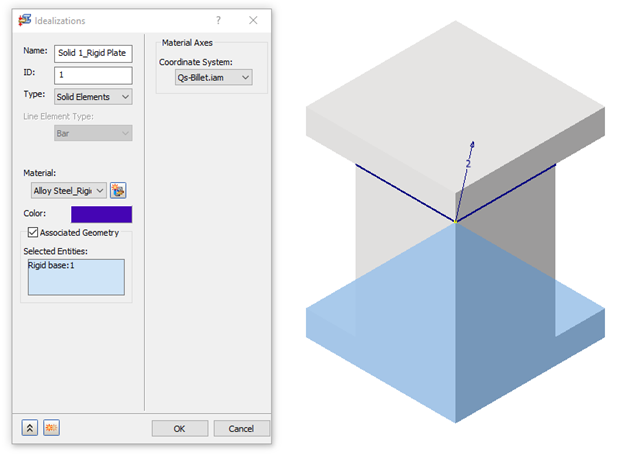

- In the

Idealizations dialog, set the following values:

- Name: Solid 1_Rigid Plate

- Type: Solid Elements

- Material: Alloy Steel_Base Rigid

- Select

Associated Geometry, then click the base of the model to apply this idealization.

- In the lower left of the

Idealizations dialog, click the New

button and set the following values for the Copper billet:

button and set the following values for the Copper billet:

- Name: Solid 2_Copper Billet

- Type: Solid Elements

- Material: Copper

- Select Associated Geometry, then click the middle part of the model to apply this idealization.

- Again click the New

button and set the following values for the Top Plate:

button and set the following values for the Top Plate:

- Name: Solid 3_Top Plate

- Type: Solid Elements

- Material: Alloy Steel_Top Plate

- Select Associated Geometry, then click the top part of the model to apply this idealization.

- Click OK to close the Idealizations dialog.

To mesh the model

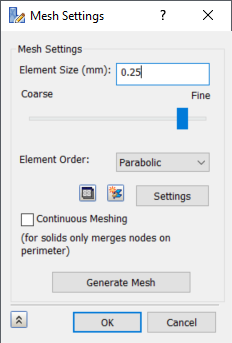

- In the

Assembly tree, right-click

.

- In the Mesh Settings dialog, set Element Size to 0.25 mm, Element Order to Parabolic, deselect Continuous Meshing, then click Generate Mesh to generate the mesh.

- Click OK to close the dialog.